|

Quantity

|

Total

|

||

|

|

|||

Automation of production processes is becoming increasingly important for companies that want to remain competitive and efficient in the market. Modern solutions allow companies to optimize their work processes, reduce costs and increase productivity, which is an important factor in achieving business goals in a world where speed and accuracy are crucial.

The Importance of Automation

There are many advantages to implementing automation in production, including the main minimization of manual labor and the reduction of the human factor in processes. This allows you to significantly increase the accuracy of tasks and reduce the likelihood of errors. Automation solutions help perform routine tasks with much greater speed and accuracy than is possible with manual process management. Thanks to this, transaction stability is achieved and the likelihood of delays or unpredictable failures is reduced.

In addition, automation allows you to significantly reduce processing time and increase the efficiency of the entire enterprise. This is especially important for large-scale production, where work processes must be as fast and efficient as possible to meet the growing demands of customers and the market as a whole.

Flexibility and adaptability of solutions

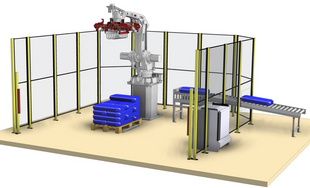

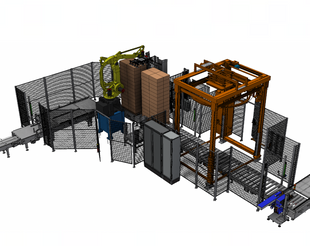

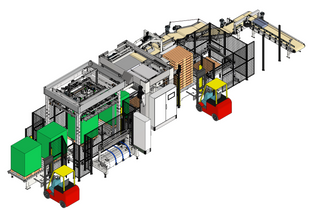

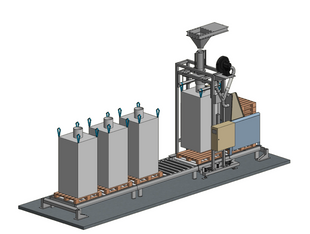

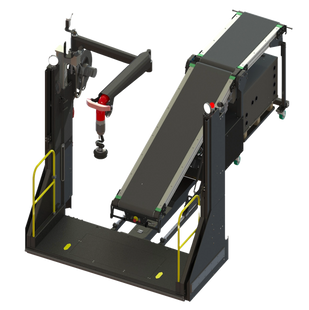

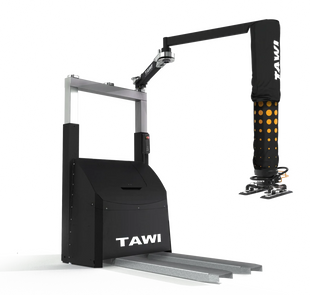

One of the key advantages of modern automated systems is their flexibility. This means that the systems can adapt to the needs of each specific enterprise. The modularity and versatility of the equipment allows it to be easily configured for specific tasks, regardless of the type of product or volume of its processing. For example, automated palletizers and operations can process products of different sizes, weights and configurations. They are capable of working with different types of packaging and ensure accurate palletizing of goods, which minimizes the risk of damage.

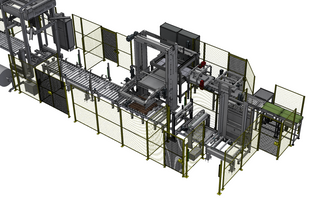

Also, the equipment used for automation can be integrated into existing production processes. This means that even enterprises that already have their own production lines can gradually automate their processes, maintaining continuity of work and avoiding significant interruptions in production. The versatility of the solutions allows enterprises to scale their production capabilities as their business grows and the market changes.

Increased productivity

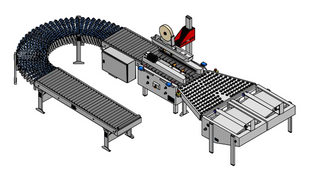

Automation can significantly increase labor productivity at the enterprise. By implementing automated solutions, such as palletizers and integrated conveyor systems, enterprises can perform tasks faster and more efficiently. This is especially important in cases where it is necessary to process large volumes of products or when the speed of order fulfillment is important. Automated systems can operate without interruption, which allows for continuous production processes and maximum productivity.

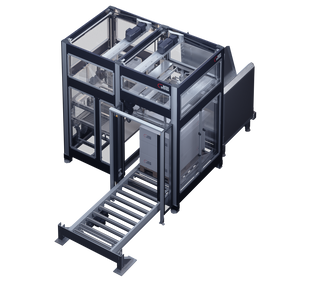

In particular, modern systems for processing and packaging products can reduce the time required to complete operations. Integrated solutions for sorting and packaging can automatically weigh, identify, and label products, allowing businesses to process orders quickly and accurately, reducing the time spent on each operation. This not only increases efficiency, but also reduces labor costs and improves overall profitability.

Improving working conditions

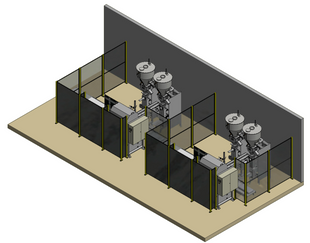

Automation also significantly improves working conditions for workers, reducing physical strain and the risk of injury. The use of automated systems and robotic solutions reduces the need for manual labor, allowing workers to focus on more critical tasks, such as product quality control and process management. This not only increases overall job satisfaction, but also helps maintain worker health.

In addition, automated solutions for packaging and handling products are designed with ergonomic requirements in mind. This means that workers can perform their duties in more comfortable conditions, reducing the risk of fatigue and occupational diseases. Reducing the physical strain on workers also helps reduce the number of accidents at work and improve overall safety.

Occupational safety

Safety is one of the main benefits of implementing automated systems at an enterprise. Modern solutions are equipped with various safety systems, such as protective fences, light barriers, and electromechanical locks. This ensures safe operation of equipment and reduces the risk of injury. For example, palletizers use protective barriers that automatically stop the system if the integrity of the protective zone is compromised. This prevents potential accidents and ensures the safety of all workers on the production line.

Automated systems also help reduce the risks associated with improper handling of equipment. They allow you to save settings for different types of products and automatically adapt to changes in production processes, which reduces the likelihood of errors and failures.

Optimization of logistics and warehousing

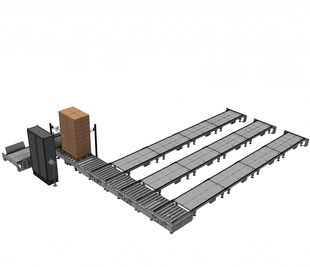

Automation is indispensable for large warehouses and logistics centers, where the speed and accuracy of order processing are important. Modern systems for automated composition include conveyors, weighing modules and barcode scanners that allow you to quickly and accurately sort products, reducing the likelihood of errors and increasing the overall efficiency of operations. This is especially important for companies operating in the retail and distribution sector, where the speed of order fulfillment is critical.

Automated warehousing solutions also allow businesses to use available space more efficiently. They can optimize the processes of storing and moving goods, which reduces warehouse maintenance costs and increases overall profitability.

Today, automation of production is not only an effective solution for increasing productivity, but also a necessity for achieving long-term success in the market. By implementing automated systems, enterprises can increase their competitiveness, reduce costs and improve the quality of their products. Automation also ensures better working conditions, increased safety and the ability to adapt to market changes.

Enterprises investing in automation receive numerous benefits, including increased efficiency, optimized work processes and reduced production costs. This is an important step to ensure stable business development and reaching new heights in today's market conditions.

To find the best solution for your production, do not hesitate to contact our experts. We will be happy to help you choose the equipment that will fully meet the specific needs of your enterprise, and also provide professional support at all stages of implementation.

SKLADPACK specializes in the sale of automation equipment, offering a wide range of solutions suitable for various production processes.