|

Quantity

|

Total

|

||

|

|

|||

Packaging equipment plays a key role in any production, since its reliability, accuracy and stable operation determine not only the safety of the product, but also its appearance. The quality of the packaging determines how the product will look on the shelf or during transportation, and whether it will be able to inspire confidence in the consumer. Therefore, by choosing the right packaging equipment, you can significantly increase the efficiency of production operations and improve the presentation of the product on the market.

Advantages of packaging equipment

1. Process optimization: The use of modern packaging machines can significantly reduce the time for packaging goods. Automated and semi-automated systems help to pack products faster, ensuring the accuracy of operations. This is especially important for large enterprises with a constant flow of goods.

2. Improved packaging quality: Modern equipment ensures that each product will be packed equally neatly and reliably. This not only improves the overall quality of the packaging, but also helps to avoid possible defects that may occur during manual packaging.

3. Possibility of individual adjustment: Thanks to a wide range of settings, packaging machines can be adapted to any production needs. You can add weighing, stacking of additional protective materials (angles or film) or automated sealing functions.

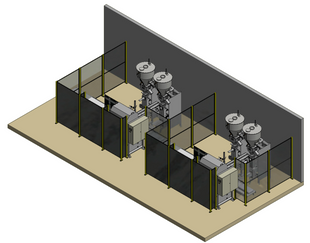

4. Automation of work processes: Many companies have already seen that investments in automation pay off quickly. Using automatic packaging machines allows you to significantly reduce the number of human resources required for packaging, which reduces costs and the risk of errors.

Stationary and mobile equipment

There are stationary and mobile packaging machines for manual and semi-automatic use. This allows companies to choose equipment depending on their needs and the specifics of the product. For example, large-sized goods that are not afraid of external influences can simply be tied with duct tape. For more fragile products, stretch film is used, which provides reliable protection and fixation.

Filling equipment

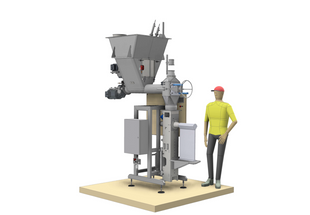

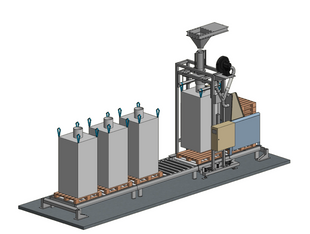

Filling equipment is no less important for any production. Its main purpose is to ensure fast and accurate dosing of products, regardless of their type. This is important for both the food and chemical industries. Using filling machines, you can be sure that each product will correspond to its declared weight, which increases consumer confidence.

Filling machines are divided into automatic and semi-automatic. Automatic units are ideal for large-scale production, where it is important to ensure high filling speed. The process is fully automatic: bags or packages are fed to the conveyor, filled with products, weighed and sealed. Such a system minimizes human involvement, which increases accuracy and productivity.

Semi-automatic units are used in smaller enterprises where production volumes are not so large. They involve human involvement in the filling process, for example, feeding bags or controlling filling. However, even in this format, semi-automatic systems significantly simplify the work and increase efficiency.

Additional benefits of packaging equipment

1. Resource saving: The high precision of automatic machines reduces the amount of packaging materials such as tape, film or cardboard used. This not only reduces material costs, but also makes production more environmentally friendly.

2. Minimization of the human factor Automation of processes reduces the risk of errors that can occur during manual work. Automatic equipment performs specified operations with high precision, which minimizes possible loss or damage to products during packaging.

3. Flexibility in use: Packaging machines are easily adapted to different types of products. From large-sized goods to small units, the machines can be customized to suit any needs.

4. Product protection: One of the main tasks of packaging is to protect products during transportation and storage. Packaging equipment ensures that the goods are not damaged during delivery and are delivered to the consumer in perfect condition.

5. Improved product presentation: High-quality packaging is not only about protection, but also about appearance. Using professional equipment, companies can create aesthetically attractive packaging, which will have a positive effect on the customer's perception of the product.

Packaging and filling equipment are the most important elements of any production. They not only increase productivity and optimize work processes, but also provide protection and an attractive appearance of products. Automated solutions allow companies to save time, resources and ensure high quality packaging, which is a key factor in today's competitive environment.