|

Quantity

|

Total

|

||

|

|

|||

Filling machines are a key element of modern manufacturing enterprises, where it is necessary to automate the process of packaging products. They allow to significantly increase productivity, reduce labor costs and ensure the accuracy of dosing of various bulk and granular materials. These machines are actively used in such industries as the food industry, construction, agriculture and the chemical industry.

One of the main advantages of filling machines is their ability to work with different types of packaging materials, including paper, plastic and polypropylene bags, as well as large big bags. Thanks to the automation of the filling processes, the machines not only provide accurate dosing of the product, but also optimize the time for each packaging cycle, which makes them indispensable for enterprises with high requirements for speed and accuracy of work.

TYPES OF FILLING MACHINES

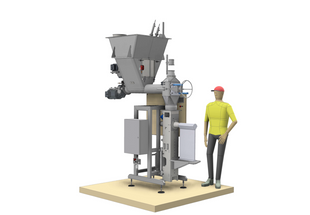

1. Filling machines for valve bags. These machines are specially designed for filling products in valve bags. They are often used in enterprises where a high level of hygiene and automation is important, for example, in the construction and food industries. These machines can work with both automatic and manual bag feeding, which provides maximum flexibility in the production process. The Skruvpac machine is a modern solution for filling valve bags. Thanks to its Swedish design and robust construction, it provides high productivity and accuracy, making it an ideal choice for enterprises in various industries. Skruvpac works with different types of materials and bags, making it a universal tool for any production.

2. Open-mouth bag filling machines. Open-mouth bag filling machines are used for automatic or semi-automatic filling of open-mouth bags. After filling, the bags can be sealed manually or automatically. These machines are especially useful for filling bulk materials such as grain, building materials or fertilizers. An example of such a machine is the Manpac, which ensures accurate and fast filling of open-mouth bags. It is characterized by high productivity and a compact design, making it convenient for use in enterprises with limited space. The machine is compatible with different types of bags and allows you to easily adjust the process to specific production needs.

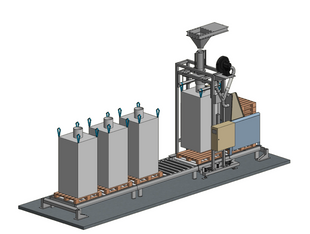

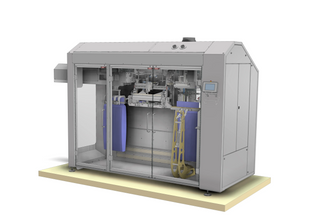

3. Big-bag filling machines. Big-bags are large bags used for transporting and storing large volumes of products. Big-bag filling machines ensure precise and fast filling of such bags, which makes them indispensable for companies working with large batches of products. One of the effective solutions in this category is the Bigpac machine, which ensures the filling of big bags with an accuracy of several hundred grams. It can work with big bags with 2 or 4 loops, and is also equipped with additional functions such as pneumatic filling and automatic weighing. Thanks to its compact design and high-quality materials, Bigpac is suitable for use in various industrial settings.

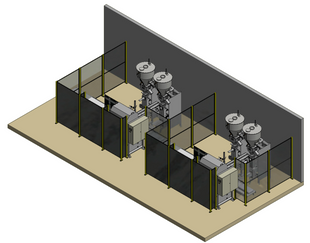

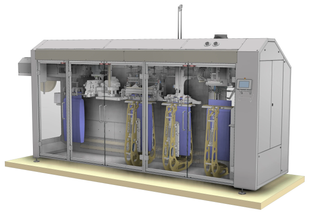

4. Integrated filling lines. For large companies that need maximum automation, integrated filling lines are the ideal solution. They combine several machines that perform various functions, such as feeding empty bags, filling them, sealing them and transporting them to the next stage of the production process. The combination of Dual Module Servus and Skruvpac machines is an excellent example of such a solution. These machines work together to provide a fully automated packaging process. The system can process up to 1,000 bags per hour, ensuring high productivity and accuracy. The machines are equipped with modern control systems, making them reliable and safe to use.

ADVANTAGES OF USING FILLING MACHINES

1. Automation of production operations. One of the main advantages of filling machines is the ability to automate most of the processes associated with product packaging. This reduces manual labor costs, reduces the impact of the human factor and increases overall production productivity.

2. High accuracy and weight control. Modern filling machines are equipped with precise weighing systems that ensure accurate product dosing. This is especially important for companies working with expensive or difficult to store materials. High accuracy helps reduce losses and ensures product compliance with standards.

3. Flexibility in using different types of packaging. Modern filling machines can work with different types of bags and containers, which allows companies to flexibly adjust production processes to specific customer requirements or product types. The ability to quickly change the machine settings to work with other types of packaging significantly increases production efficiency.

4. Improved hygiene in production. Many filling machines are designed to meet strict hygiene requirements, especially those used in the food industry or for packaging medical and pharmaceutical products. Using stainless steel machines and other hygienic materials ensures easy cleaning and maintenance, which helps maintain high standards of cleanliness in production.

5. Saving time and resources. Automation of packaging processes allows you to significantly reduce the hour for packaging each unit of product, which increases the overall productivity of the enterprise. This also helps reduce personnel and equipment maintenance costs, which is an important factor for large manufacturing enterprises.

Filling machines are indispensable equipment for enterprises seeking to improve the efficiency of their production processes. They provide high productivity, accuracy and flexibility, which allows you to meet different business needs. Due to the ability to automate packaging processes, these machines reduce manual labor costs, reduce the number of errors and improve the overall quality of products.

If you are looking for reliable equipment for automating packaging processes, SKLADPACK offers a wide range of modern packaging machines that meet the highest quality and productivity standards.