|

Quantity

|

Total

|

||

|

|

|||

Warehouse logistics requires modern and comprehensive solutions to optimize processes, increase productivity and ensure safety for both personnel and equipment. Innovative technologies significantly facilitate daily operations such as packaging, cargo handling, order processing and container unloading. SKLADPACK offers a wide range of equipment that will help achieve new levels of efficiency in warehouse management. This solution includes packaging stations, vacuum lifters, order picking systems and pallet management that make warehouse work more organized, safer and more productive.

KEY SOLUTIONS FOR WAREHOUSE LOGISTICS

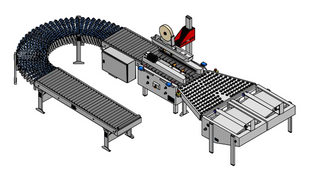

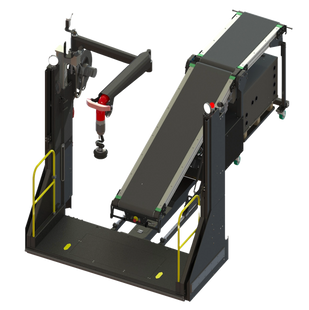

1. Double-seat packaging station - designed for simultaneous work of two operators and provides versatility in handling boxes of any size. It consists of packing tables, a conveyor and a sealer for cardboard boxes. This solution allows you to reduce order processing time, ensure more organized work and increase overall warehouse productivity. The station is designed with ergonomics in mind, which ensures comfortable work for personnel, reducing the risk of injury and increasing overall job satisfaction. Vacuum container unloader - ensures safety and efficiency when unloading goods from containers or trucks, minimizing the risks to personnel that arise during manual lifting. This solution optimizes the unloading process, reduces the need for a large number of workers and increases overall productivity.

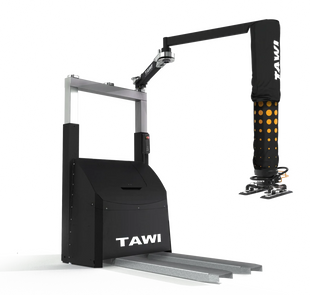

2. High-frequency vacuum lifters MHL40 - ensure fast lifting of boxes and other packaged goods. Due to their mobility, these systems can be used in any area of the warehouse, which makes them universal and indispensable for warehouse centers where the speed of order processing is important. The lifts are easy to move, which saves space and minimizes labor costs. The lifts are designed for easy use, reducing the physical strain on personnel. 3. Mobile vacuum order picking systems - The VM50 mobile order picking system allows you to quickly and easily process orders from the racks thanks to a vacuum lifter installed on a mobile platform. This system is compatible with all types of forklifts, making it a flexible tool for large warehouses. The VM50 is ideal for working in confined spaces and ensures reliable and safe lifting of goods, reducing the need for manual labor.

4. EVOLIFT electric lifts - are universal solutions for moving boxes, crates and other goods. They are made of high-quality materials such as aluminum and stainless steel, making them reliable and durable. The lifts can be easily adapted to different requirements thanks to their adjustable height and a wide range of grippers for different types of goods. This allows EVOLIFT to be used to handle any type of material, from food products to large-sized goods.

5. PalManager autonomous pallet magazines - provide automatic stacking or unloading of pallets. These systems allow you to store up to 24 pallets and use them when needed, which significantly increases the efficiency of warehouse operations. Autonomous pallet magazines help reduce pallet servicing time and minimize the risk of industrial injuries.

PRINCIPLES OF OPERATION AND ADVANTAGES OF INNOVATIVE SOLUTIONS

1. Increased productivity: Innovative warehouse logistics solutions significantly reduce order processing time, reduce labor costs and increase staff efficiency. Vacuum lifters and mobile order picking systems allow for fast and safe handling of large volumes of goods, which speeds up logistics processes.

2. Safety: Vacuum lifters and automated systems minimize the risks associated with manual work, reducing the risk of industrial injuries. Ergonomic equipment designs ensure comfortable work for staff, reducing physical strain and fatigue.

3. Mobility and flexibility: Mobile solutions such as vacuum lifters and order picking systems allow for easy movement of equipment between different areas of the warehouse. This allows for more efficient use of workspace and adaptation of processes to the specific needs of the enterprise. 4. Cost reduction Automation of processes such as pallet stacking or goods handling reduces the number of personnel involved and reduces maintenance costs. In addition, polyethylene solutions for stacking and protecting pallets ensure durability and reduce the need for equipment repair.

5. Ergonomics: The equipment is designed with employee comfort in mind. Two-seat packing stations, vacuum lifters and electric lifts reduce the level of physical strain, which has a positive effect on productivity and reduces the risk of occupational diseases.

Innovative warehouse logistics solutions from SKLADPACK provide comprehensive optimization of work processes, increase productivity and ensure safety in the workplace. The introduction of modern technologies such as vacuum lifters, mobile order picking systems and automated pallet stores allows enterprises to significantly improve the efficiency of logistics operations, reduce maintenance costs and provide comfortable working conditions for personnel.

Contact SKLADPACK to implement the best solutions for your warehouse!