|

Quantity

|

Total

|

||

|

|

|||

Shrink wrap machines play an important role in modern manufacturing, providing reliable and efficient packaging of products on pallets. They are used in various industries, such as food, pharmaceutical, construction, logistics and many others. The principle of operation of shrink wrap machines is to shrink a special polyethylene heat-shrink film onto pallets with finished products. This ensures reliable fixation of the cargo on the pallet, protection from moisture, dust and mechanical damage during transportation or storage.

One of the main problems with traditional shrink wrap machines is the use of gas, which can be dangerous for the operator and the production process as a whole. However, our shrink wrap machines are distinguished by an increased level of safety due to the use of special burners with gas compensators, minimizing the risk of dangerous situations.

MAIN TYPES OF SHRINK WRAPPING MACHINES FOR PALLET PACKAGING

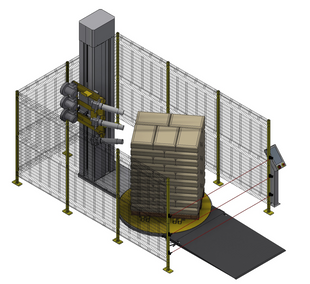

Semi-automatic shrink wrap machines: suitable for medium-sized enterprises where efficiency and flexibility are important. These machines partially automate the packaging process, leaving the operator with the ability to control some parameters manually. The main stages of packaging, such as pallet feeding and film shrinkage, are automatic, which allows for a significant reduction in product packaging time.

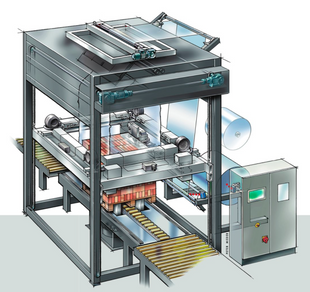

Automatic shrink wrap machines: the ideal solution for large enterprises with a high volume of products. They fully automate the entire process, from pallet feeding to final film shrinkage. Due to the high operating speed and minimal intervention from the operator, these machines ensure continuous operation of production lines. Automatic shrink wrap machines can handle loads of different sizes and weights, making them a universal solution for any type of production.

ADVANTAGES OF USING SHRINK WRAPPING MACHINES

1. Reliable fixation of the load: Shrink wrap machines provide high stability and reliability of load fixation on the pallet. During the shrinking process, the film tightly covers the product, preventing its displacement or damage during transportation. This is especially important for products that may be vulnerable to mechanical damage or displacement, such as fragile goods or liquids.

2. Protection from external factors: Shrinking the polyethylene film on the pallet provides additional protection for the product from moisture, dust and contamination that may occur during storage or transportation. This makes shrink packaging an ideal choice for products that require long-term storage or transportation over long distances.

3. Increased productivity: The use of shrink wrap machines can significantly increase production productivity due to the automation of packaging processes. Machines can operate continuously, which reduces the time for each package and allows companies to process more orders in a short period. Thanks to this, companies can significantly increase their competitiveness in the market.

4. Resource savings: Shrink wrap machines help optimize the use of packaging materials. Fine-tuning the process allows you to reduce film costs and reduce waste, making the process more economical and environmentally friendly.

5. Versatility and flexibility: With the ability to use different types of film and adjust the parameters of the packaging process, shrink wrap machines can easily adapt to different types of products. This makes them a universal solution for enterprises of any type, regardless of the specifics of production.

SHRINKING MACHINE SAFETY

Gas compensator technology: ensures stable pressure and uniform gas flow, which minimizes the risk of emergency situations. These systems automatically control the gas supply and respond to pressure changes, which reduces the likelihood of any unwanted incidents during machine operation. This makes our equipment not only efficient, but also maximally safe for use in any production conditions.

In addition, SKLADPACK shrink wrap machines have additional safety systems, including automatic shutdown of the equipment when malfunctions or discrepancies in the operation of the burners are detected. These functions can significantly increase the level of safety in production and prevent possible accidents.

SKLADPACK offers a wide range of shrink wrap machines that ensure efficiency, reliability and safety in production. Our equipment meets the highest quality and safety standards, and thanks to the use of advanced technologies, we can guarantee the smooth operation of the machines for many years.