|

Quantity

|

Total

|

||

|

|

|||

Country of origin: Germany

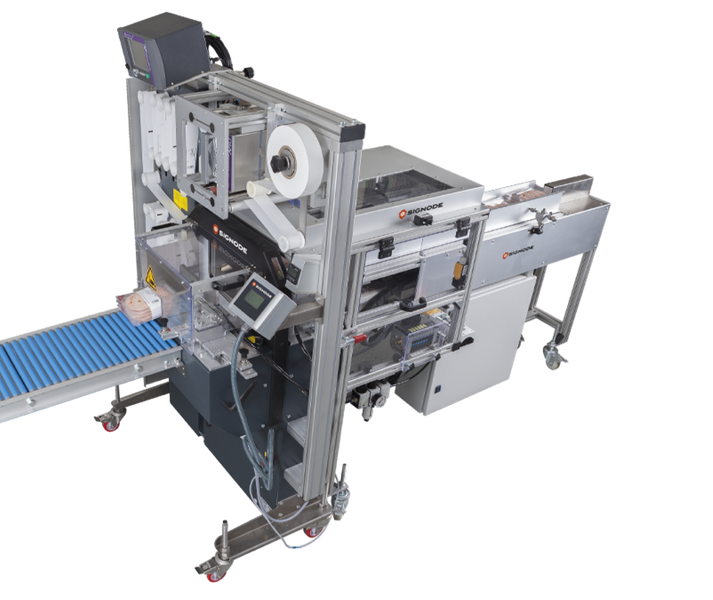

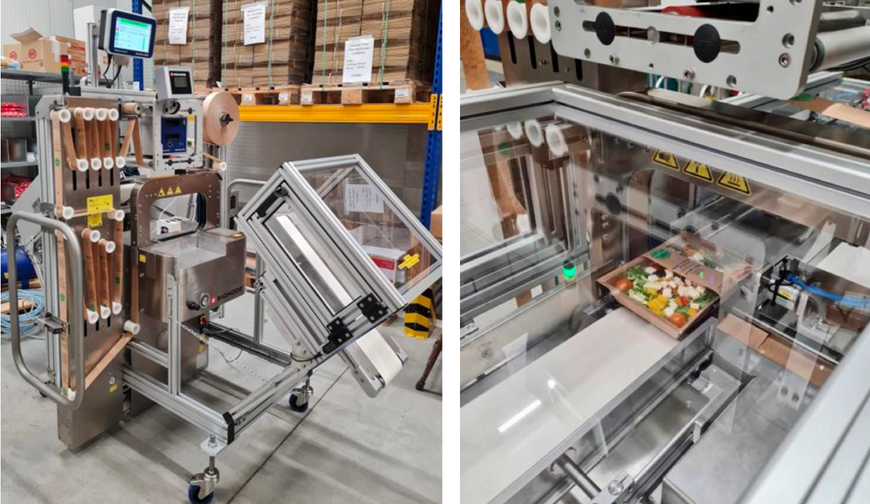

Packaging line BA 32-25-48 is designed for an automated packaging process. Products are placed on the conveyor belt moving in the direction of the flow. The system ensures precise product positioning using a 90-degree shift, enabling the product to be placed at the wrapping station. A pneumatic device transports the product to the wrapping point, and after wrapping, the units are transported further.

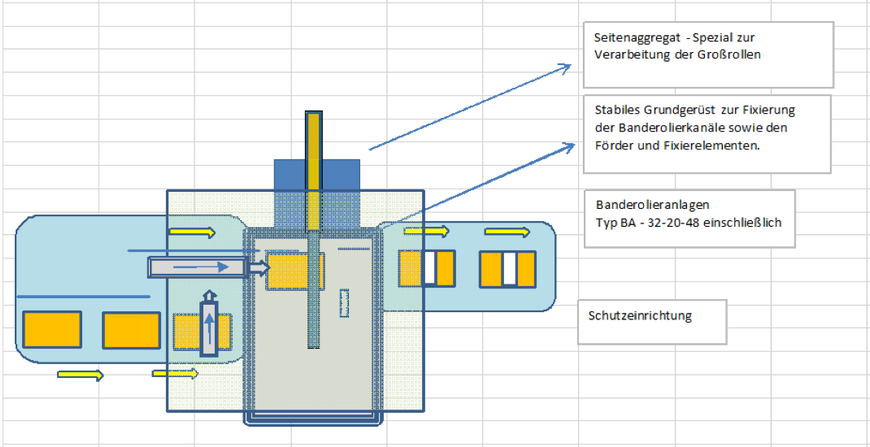

Main components:

- Specialized side unit for handling large rolls

- Stable base for securing wrapping channels and conveyor elements

- Wrapping system type BA 32-20-48 included

- Protective device

Advantages:

1. No top contact with the product

2. Easily adjustable for different cup sizes

3. Separation and alignment of cups due to precise positioning

Operating process:

1. Product Feeding:

Products are automatically fed onto the input conveyor, which is approximately 700 mm in length. The conveyor is equipped with adjustable side guides to accommodate different product sizes. This ensures precise delivery of products to the banding device.

2. Integration of Banding and Thermal Transfer Devices:

Products are transported to the banding zone where they are positioned for band application. The electric linear block handles product positioning. Products of various sizes can be accommodated thanks to adjustable equipment settings.

3. Banding Process:

The BA 32-20-48 machine uses a specialized band (with widths of 28 mm, 48 mm, 75 mm, or 100 mm) that is securely sealed around the product using a heating coil. The sealing temperature is adjustable, allowing adaptation to different packaging materials.

4. Information Printing on the Band:

Important data such as logos, barcodes, serial numbers, or production dates can be printed directly on the band using the integrated thermal transfer printer, which supports printing lengths up to 75 mm.

5. Output of Finished Products:

After the banding process, the products are transported on an output conveyor, approximately 1000 mm in length. This conveyor is equipped with side guides and plastic rollers for smooth product movement toward further packaging or storage.

6. Control and Safety:

The system is controlled by Siemens PLC technology, providing precise operation control, including speed and temperature adjustments. For safety, the system includes a protective casing covering all moving parts, reducing operator risks.

System advantages:

- Automation: Ensures high productivity with minimal manual labor

- Flexibility: The system adapts to various product sizes and packaging requirements

- Precision: Adjustable parameters ensure perfect sealing and information application on the band

- Energy Efficiency: Low energy consumption makes the system cost-effective

- Safety: The protective casing and control system guarantee a high level of safety in production

Technical specifications:

- Product feeding device: Conveyor system, 700 mm in length, adjustable +/- 100 mm, with adjustable side guides

- Stable base: Strong foundation with adjustable stabilizing legs for system fixation, height adjustable

- Electric linear block: Electrical linear system for inserting and positioning products, adjustable length, inline variant

- Output conveyor technology: Conveyor for output, 400 mm in width, 1000 mm in length, plastic rollers, galvanized axes

- Control system: Siemens PLC with sensors and frequency converters for motors

- Protective casing: Ensures operational safety

- Product width: Ranges from 30 mm to 320 mm

- Product height: Ranges from 5 mm to 200 mm

- Band width: Standard 48 mm, other options upon request

- Material thickness: Paper or film 50-70 g/m², film up to 50 microns

- Sealing type: Heating coil for secure sealing

- Band tension adjustment: Smooth adjustment for optimal packaging

- Sealing temperature: Adjustable for different materials

- Working speed: Up to 28 cycles per minute

- Energy efficiency: 500 W

- Air pressure: Compressed air 6 bar

- Foot switch: Convenient foot control

- Print control system: Ensures precise positioning of printed elements

- Automatic stamp cleaning: Stamp cleaning after each operation

- Stainless steel: Increases durability

- Band roll holder: For easy replacement of the band

- Additional display: For system operation control

- Node insulation: Protection against moisture and residual materials

- Thermal transfer printer: Prints information up to 75 mm

- Alternative thermal printer: Suitable for printing basic information such as serial numbers

We will be happy to prepare an individual offer for consumables based on your PDF layout. SKLADPAСK offers not only equipment, but also comprehensive services for setting up and launching the system on your.

Delivery time from the manufacturer's factory: 12-16 weeks. We will inform you of the exact delivery date after placing your order on the website.