|

Quantity

|

Total

|

||

|

|

|||

Automation of production processes in modern conditions is becoming a decisive factor for ensuring the competitiveness of companies. This applies to all industries - from the food industry to logistics, where speed, accuracy and efficiency are key aspects of successful operations. One of the most important elements of automation is the implementation of conveyor systems that ensure uninterrupted transportation of goods, packaging and processing of products. The SKLADPACK company specializes in the development and implementation of innovative solutions for the automation of production processes, in particular conveyor systems that allow enterprises to increase productivity, reduce costs and optimize work processes.

Conveyor systems: the key to production optimization

Conveyor systems are an indispensable solution for transporting products within production facilities. They allow you to optimize logistics, reducing manual labor and minimizing the time it takes to move goods between different stages of production. Automated conveyor systems can operate continuously, ensuring fast and efficient movement of goods, which is important for enterprises with large production volumes.

The systems offered by SKLADPACK are reliable, flexible and can be adapted to any customer needs. They can be configured for various types of goods, from light boxes to heavy pallets, and can also operate under increased load conditions while maintaining high productivity.

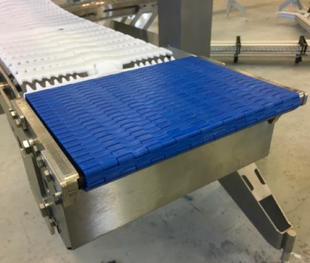

One of the most popular solutions on the market is modular conveyor systems. These conveyors can be used in many industries, including food, pharmaceutical, automotive, as well as logistics and warehousing. They provide the ability to transport different types of goods, including boxes, bags, pallets, as well as liquid or bulk materials.

The main advantage of modular conveyors is their flexibility. The systems are easily adapted to specific production conditions and customer requirements, which allows you to optimize the workspace and ensure maximum efficiency of the enterprise. The modular design allows you to quickly change the conveyor configuration by adding or removing sections depending on current needs.

The main advantages of modular conveyor systems

1. Flexibility in configuration. Modular conveyor systems can be easily adapted to specific production processes. This is especially important for enterprises that constantly change the range of products or the sizes of the transported goods.

2. Transportation of goods of different weights and sizes. Modular conveyors can transport both light and heavy loads thanks to the use of various types of belts, rollers and chains. This makes them a universal solution for any industry.

3. Reliability and durability. Conveyors are made of high-quality materials, which ensures long-term operation even under intensive use. They are designed to meet high reliability requirements, allowing enterprises to operate without interruption.

4. Ease of maintenance. Conveyor systems have a simple design that allows for easy maintenance and minimizes the hour for repair work. This is important for enterprises seeking to reduce the hour of downtime and maintain a high level of productivity.

5. Space saving. Modular conveyor systems allow for efficient use of production space, since they can be configured to specific enterprise conditions, including operation in confined spaces or with different height levels.

6. Energy efficiency. Modern modular conveyors consume a minimum of energy, which reduces operating costs and reduces the impact on the environment.

Plate conveyors: solutions for specific production needs

In addition to modular systems, SKLADPACK also offers specialized solutions, in particular plate conveyors. They are used where high precision and reliability are required during the transportation of goods. Plate conveyors are especially effective in companies producing products that require special handling during transportation, such as beverages, food products or building materials.

The main advantages of plate conveyors

- High conveying precision. Thanks to the design of the plates, these conveyors ensure uniform movement of goods without jumps and jerks.

- Reliability under intensive use. Plate conveyors can withstand heavy loads and can operate under conditions of constant high intensity.

- Possibility of use in aggressive environments. They are resistant to moisture, chemicals and high temperatures, which makes them ideal for use in difficult conditions.

Conveyor systems from SKLADPACK can be easily integrated into existing production lines. They support various control protocols, which allows them to be quickly configured to work with other automated systems in the company. This allows you to create a single network for controlling and monitoring production processes, ensuring maximum efficiency and transparency in work.

In addition, automated conveyor systems can be easily programmed for different operating modes, which allows you to quickly adapt them to changes in production processes. This is especially useful for companies working with a wide range of products and changing types of cargo depending on the season or market needs.

SKLADPACK company offers a full range of services from project development to implementation and maintenance. Thanks to many years of experience in the market, we can offer customized solutions for the automation of any production processes that will be as efficient and profitable for your business as possible.

SKLADPACK is a reliable partner for companies seeking to optimize their production processes, increase efficiency and reduce costs. We offer only high-quality equipment that meets the latest standards and market requirements.

When ordering automation equipment from SKLADPACK, you receive reliable high-tech solutions adapted to the specific needs of your business. Our specialists will help you at every stage - from design to system launch.