|

Quantity

|

Total

|

||

|

|

|||

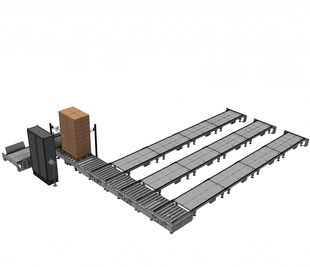

Product sorting lines are high-tech solutions that automate key stages of product handling in a warehouse. They integrate various components such as conveyor systems, weighing modules and barcode scanners to ensure accurate and fast transportation, weighing and identification of products. By fully automating these processes, companies can minimize human errors, increase operational efficiency and reduce manual labor costs.

KEY ASPECTS OF SORTING LINES

1. Process automation - sorting lines ensure fast and accurate task execution without operator intervention. Due to this, the time for product handling is significantly reduced, and the number of human errors is reduced to a minimum. This allows companies to focus on strategic tasks, leaving routine operations to automation systems.

2. Accuracy and control - integrated weighing control and barcode scanning systems ensure that each product in the warehouse is accurately weighed and identified at all stages of processing. This ensures high data accuracy and process control, which allows for efficient management of warehouse movement and reduced risks of losses.

3. Cost optimization - automated sorting lines can significantly reduce manual labor costs, as the main operations are performed automatically. This not only increases warehouse efficiency, but also helps minimize equipment maintenance costs and reduce risks associated with accounting errors or improper transportation of goods.

4. Flexibility and adaptation - sorting lines are easily integrated into existing warehouse infrastructure and can be configured to meet the specific needs of your enterprise. This allows you to quickly adapt the system to new conditions or changes in business processes without stopping core operations.

5. Safety and reliability - automated sorting lines not only ensure accuracy and speed of processing, but also increase the level of safety in the warehouse. Thanks to sensor systems and automated movement control, personnel and equipment are reliably protected from accidents and damage.

Automated sorting lines include a wide range of solutions for processing finished products. They provide:

- Transportation: Reliable conveyor systems allow for fast and safe transportation of products across warehouses, reducing the risk of damage and reducing the time it takes to move goods.

- Weighing and identification: Automated weighing modules and barcode scanning systems ensure that each product is accurately weighed and identified at all stages of processing.

- Monitoring and control: Integration with software allows for full control over each stage of the sorting process, ensuring continuous monitoring and quick response to changes.

Benefits for your business

1. Increased productivity: Automated sorting lines can significantly reduce order processing time, increasing the efficiency of all operations.

2. Accurate product accounting: Automated control systems ensure accurate weighing and identification of goods, which reduces the risk of errors and losses.

3. Reduced costs: By minimizing manual labor and reducing the number of errors, enterprises can reduce product processing costs.

4. System flexibility: Sorting lines easily adapt to changes in production or warehouse processes, allowing you to quickly respond to new challenges.

5. Safe working environment: Integration of automated solutions improves personnel safety, reducing the risk of injury and equipment damage.

With our experience and professionalism, you can significantly improve the organization of work at your enterprise and ensure maximum efficiency of sorting processes. Contact SKLADPACK to purchase the most modern solutions for product sorting!