|

Quantity

|

Total

|

||

|

|

|||

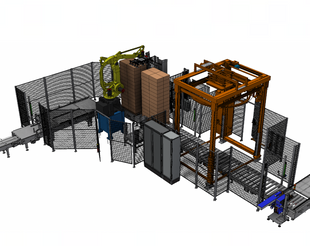

Automation of crate handling processes is a fundamental element of modern manufacturing and warehousing operations. Crate handling lines include a set of equipment that ensures efficient transportation, palletization and packaging of pallets with finished products. This solution allows enterprises to increase productivity, reduce manual labor costs and minimize the number of errors in the product handling process.

The use of such lines is especially relevant for the food, chemical, pharmaceutical and other industries where it is necessary to process large volumes of products, ensuring the speed and accuracy of each stage. A high level of automation allows for significant optimization of logistics and production processes, ensuring maximum efficiency and minimizing risks.

Crate handling lines consist of various elements that perform basic operations: from automatic transportation to palletization and wrapping of products for storage or shipment. Thanks to the integration of modern technologies, such lines are capable of processing various types of products with high accuracy and minimal human intervention.

Automated systems for palletizing crate products can include classic palletizers or modern robotic solutions using robotic palletizers. Each type of equipment has its own advantages and capabilities, allowing companies to choose the solution that best suits their needs. The lines ensure fast, accurate and safe stacking of boxes on pallets for further transportation or storage, and automated wrappers ensure the tightness and stability of the packed pallets.

Main advantages of automated lines for handling products in boxes

1. High productivity. Automated lines allow you to handle large volumes of products much faster than is possible manually. Thanks to this, enterprises can significantly increase production volumes, reducing labor costs and reducing the time required to perform routine operations.

2. Accuracy and reliability. Modern lines are equipped with precise dosing, weighing and packing systems in boxes, which minimizes the number of errors and ensures high quality packaging. This is especially important for enterprises working with fragile goods or products that require careful handling.

3. Reducing manual labor costs. Due to the high level of automation, lines for handling boxes can significantly reduce dependence on the human factor. This reduces labor costs and reduces the risk of errors caused by human intervention in the process.

4. Flexibility and adaptability. Lines for handling products in boxes can easily adapt to different types of products and packaging. This allows enterprises to quickly respond to changes in market requirements, quickly reconfiguring equipment to new needs without significant modernization costs.

5. Safety and security. The use of automated case handling systems significantly increases the level of safety in production. Modern equipment minimizes risks to workers, since most physically difficult or dangerous operations are performed by machines, which reduces the likelihood of injuries and incidents.

6. Integration with other systems. Case handling lines can be easily integrated with existing production lines and logistics processes. This allows enterprises to automate the entire product handling cycle - from production to storage and transportation.

7. Reducing packaging and storage costs. Thanks to the use of automated pallet wrapping systems, products in boxes are securely fastened to pallets, which ensures their protection during transportation and storage. This reduces the cost of packaging materials and minimizes the risk of product damage.

Automation of the palletizing process is an important part of modern logistics and production lines. Both classic palletizers and palletizer-works can be used for palletizing products in boxes.

Both approaches have their advantages

- Classic palletizers. These are reliable and efficient systems that are used to stack boxes on pallets. They ensure stable operation with high productivity and are the optimal solution for companies with a large volume of products. Such systems can be easily integrated into existing production processes and ensure precise stacking of boxes without the risk of damaging the products.

- Robotic palletizers. They provide even greater elasticity and precision in palletizing actions. Due to the ability to work with several product flows simultaneously, robotic systems can be used for complex production lines. They allow you to easily set up palletizing schemes and quickly adapt to changes in the production process. Robotic palletizers are the ideal choice for companies seeking maximum flexibility and efficiency.

The SKLADPAСK company offers modern solutions for the automation of product handling in boxes. Our lines combine high standards of quality, productivity and safety, which allows companies to achieve maximum results in their activities. We offer equipment for transporting, palletizing and wrapping products, which increases the efficiency of the production line.