|

Quantity

|

Total

|

||

|

|

|||

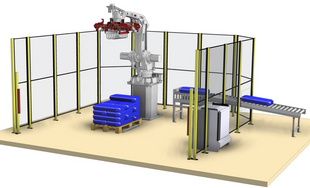

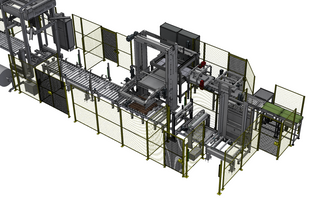

Automation of production processes is a necessity for companies seeking to achieve maximum efficiency and precision. Especially important are bag processing lines, which allow companies to handle large volumes of bulk or packaged materials, ensuring high productivity and cost reduction. Thanks to modern automated bag processing systems, companies can significantly optimize their operations, minimize human intervention and increase safety.

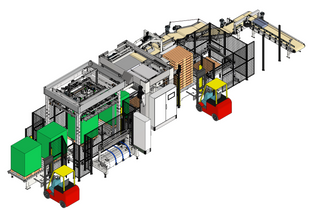

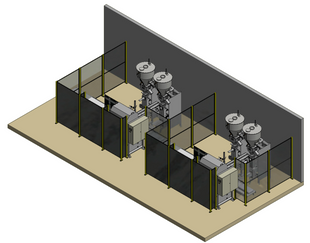

Bag processing lines are complex automated systems that are designed for filling, weighing, transporting and packaging products in different types of bags. Such solutions are used in various industries, in particular, in the chemical, food, construction and agricultural sectors. The lines can be adapted to any type of product - from bulk materials to large volumes of products that require careful accounting and weighing.

Automation of processes allows you to significantly reduce labor costs and increase the accuracy of product processing, which is critical to ensuring competitiveness in the market. Bag processing systems minimize the risk of errors and ensure stable operation even in difficult production conditions.

Main advantages of automated lines for processing products in bags

1. High productivity. Lines for processing bagged products ensure fast and uninterrupted operation, allowing you to pack and transport up to 3,000 bags per hour. This is especially important for enterprises with high production volumes, where every minute of downtime can lead to financial losses.

2. Accuracy and efficiency. Thanks to integrated weighing systems and automatic control, each bag is filled exactly according to the specified parameters. This ensures high dosing accuracy, which is a key factor for enterprises working with valuable or hazardous materials.

3. Reduced labor costs. Automation of product processing processes can significantly reduce dependence on human labor. The system performs all basic operations - from feeding bags to filling and packaging, which allows enterprises to optimize personnel costs and reduce the number of errors.

4. Safety and reliability. Automated lines reduce the risk of industrial accidents, since most dangerous transactions are performed by machines. This is important for enterprises that process heavy or toxic materials that require special processing conditions.

5. Flexibility and adaptability. Modern bag processing lines can be easily configured to handle different types of bags and products. This allows companies to adapt to changing market requirements or switch to processing new types of products without the need for significant upgrades.

6. Reduction in waste and material savings. Thanks to optimized packaging processes, the lines minimize the use of packaging materials such as film or fabric. This not only reduces material costs, but also reduces the negative impact on the environment.

7. Possibility of integration into existing production lines. Modern bag processing lines can be easily integrated into the existing infrastructure of the enterprise, which simplifies their implementation and reduces the costs of upgrading production facilities.

Bag processing lines perform the following main operations

- Filling products into bags - automatic filling of bags with various types of materials, from bulk to powder;

- Weighing products - precise dosing in accordance with the established parameters for each type of product;

- Product transport - automatic movement of bags between different stages of the production process using conveyors; - Preparation for shipment - automated palletizing systems place bags on pallets for further transportation to the warehouse or to the customer.

SKLADPACK is a leading supplier of equipment for automation of bagged product handling processes. Our solutions help enterprises significantly increase productivity, reduce production costs and provide high quality customer service.

We offer comprehensive solutions that include all the necessary equipment for full automation of bagging, weighing and packaging processes. Our systems are designed taking into account modern safety and efficiency standards, ensuring stable operation at all stages of production.

When purchasing equipment for automation of bagged product handling from SKLADPACK, you get:

- Reliable and highly efficient systems that ensure uninterrupted production processes.

- Ability to configure and adapt equipment to the specific needs of your enterprise.

- Comprehensive technical support and maintenance at all stages of implementation and operation.

- Guarantee of equipment quality and durability.

Automatic lines for bagged product handling are a strategic step towards increasing efficiency, reducing costs and improving safety at the enterprise. By implementing such systems, companies can achieve significant results in reducing operating costs and increasing productivity. Skladpack offers high-quality automation solutions that will help your business operate at a new level of efficiency and stability.