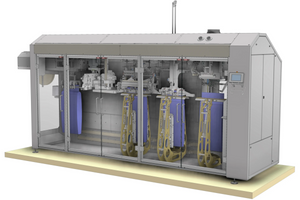

The high-performance stretch wrapping machine Octopus 1850T is the highest-speed series of ring wrappers from Haloila. The model has a capacity of up to 150 pallets/hour.

The ring technology allows for top-down, bottom-up or single-layer wrapping for significant savings. The Octopus 1850T is equipped with two S-type carriages, which allow for easy, fast and safe roll changes. Each carriage is equipped with a No Touch No Tail contactless seam welding device. The contactless seam welding technology does not leave dangerous film tails and does not allow the heat sealing device to touch the load.

The OctoFACE HMI interface is easily adapted to the user's needs, informative and easy to use, which reduces downtime and allows troubleshooting independently, without the intervention of technical personnel.

The high-performance Octopus 1850T wrapper is equipped with a pre-tensioning system, it guarantees:

- Consistently low film consumption;

- Control of packaging costs;

- Consistently high packaging quality thanks to first-class Bluetooth data transmission;

Octopus 1850T wrapper control:

- The latest and most modern control system;

- Color HMI display, with excellent graphics;

- Simple menu navigation via graphics and text (self-explanatory);

- Performance data, availability, statistics, error messages.

Benefits:

- Optimized load stability during transport;

- Multiple wrapping methods - wrapping can be started and stopped at any height;

- Control of the continuous laying force of the film using wireless technology;

- Modular concept, the machine can also be subsequently equipped with various options;

- No interruptions in production due to manual intervention or film changes, fully automatic process during production;

- Increased flexibility and productivity, as well as availability (up to 99.95%);

- Relief of service personnel.