|

Quantity

|

Total

|

||

|

|

|||

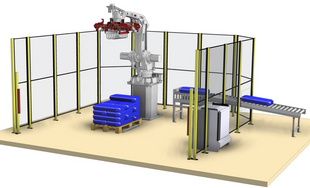

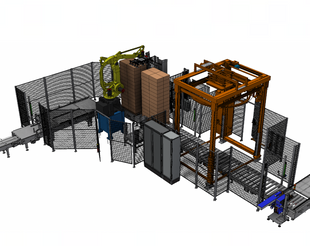

Robot palletizers are advanced solutions for automating the process of palletizing products, which significantly increase the efficiency of production lines. Such systems allow for fast and safe processing of products of different sizes and weights, which makes them universal for use in large enterprises with high requirements for the speed and accuracy of palletizing. Thanks to palletizers, it is possible to organize the processing of products from several streams simultaneously, which is especially important for enterprises with complex production processes.

The main advantages of robot palletizers are their speed, accuracy and the ability to work in limited spaces. The systems are able to service several product streams simultaneously, placing products on different pallets with maximum efficiency. This versatility is ensured by specially designed grippers that allow working with various types of products - from cardboard boxes to trays and bags. Such flexibility allows adapting robotic systems to the specific needs of the customer.

Advantages of robot palletizers

1. High stacking speed. Palletizing robots are capable of operating at high axial speed, which significantly reduces the time of one wrapping cycle and increases the overall productivity of the enterprise. This is especially important for large-scale production, where every second counts.

2. Ability to work with several product flows simultaneously. Robots can service several flows, placing products on different pallets. This allows for the efficient use of equipment in enterprises with different production lines.

3. Compactness and space saving. Thanks to the 360° coverage area, palletizing robots can work even in limited space, which makes them ideal for enterprises with compact production sites.

4. Flexibility in working with different types of products. Robots are equipped with special grippers that can be configured according to the type of product. This allows for efficient work with cardboard boxes, bags, trays, pallets and other goods.

5. Automation and accuracy. Palletizing robots provide high accuracy in product stacking, which is especially important for maintaining its integrity during transportation. Programmable control systems allow you to fine-tune the stacking process and quickly adapt to changes in production.

6. Integration with existing production lines. Robots can support various network protocols, such as DeviceNet, ControlNet, Profibus-DP and Interbus-S, which ensures easy integration into the existing infrastructure of the enterprise.

One example of such systems is the RoboPAL robot palletizer. This is a high-power four-axis robot, specially designed for working with large volumes of products. RoboPAL can process up to 50 pallets per hour, which significantly increases the speed of production processes. Thanks to high-speed axis drives, the robot is able to reduce the stacking cycle time, which allows it to work efficiently even under high loads.

Key features

- Processing speed. The robot ensures fast stacking of products, which allows achieving a productivity of up to 50 pallets per hour.

- Flexible working range. The 360° working range allows for simultaneous work with several product streams, which allows for the efficient use of equipment even in limited space.

- Autonomous control software. Thanks to the software, the robot can easily adapt to changes in palletizing patterns or product configurations, ensuring maximum flexibility.

To handle different types of products, the palletizing robot uses special grippers, developed individually for each type of product. This avoids frequent reconfiguration of the equipment and ensures stable operation even when production tasks change. The gripping system has several levels of protection against damage to the product, which guarantees its integrity during the stacking process.

Particular attention should be paid to palletizing systems for bags, which are often used in production processes. Special grippers for bags allow you to carefully take products and stack them on pallets without deformation or damage. Thanks to the design of hardened anodized aluminum, which reduces the weight of the equipment, such systems ensure high productivity and reduced energy consumption.

SKLADPACK company offers innovative solutions for the automation of palletizing processes, including palletizing robots that meet the highest quality standards. Our systems are easily integrated into a production line of any complexity and will help significantly increase the efficiency of your enterprise. All work can be customized to the specific needs of the customer, which ensures maximum flexibility and adaptability to various production conditions.

When ordering palletizing equipment from SKLADPACK, you get

- Reliable and high-tech solutions for palletizing automation.

- Support at every stage - from design to implementation and maintenance.

- Possibility of integrating systems into existing production lines with minimal costs.

Optimize your production processes with robotic palletizers from SKLADPACK and reach new heights of productivity and efficiency.