|

Quantity

|

Total

|

||

|

|

|||

Country of origin: Finland

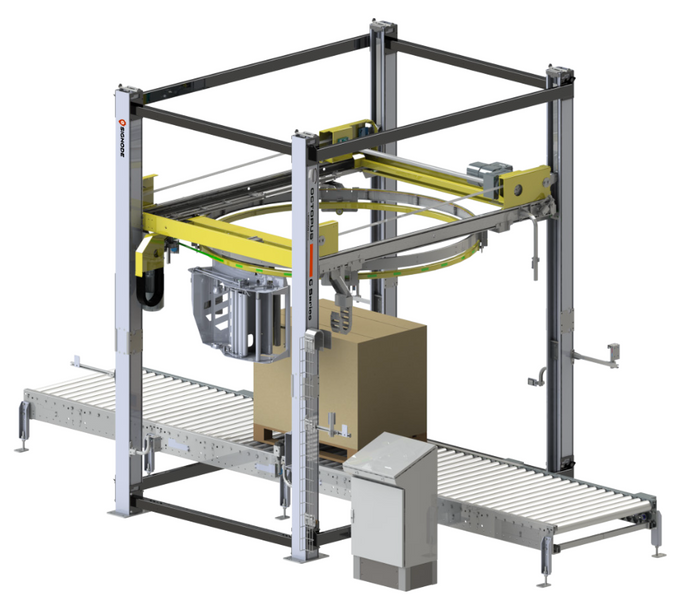

Automatic rotating ring stretch wrap machine Octopus Compact 20 uses the latest technology with the classic ring wrapping method to ensure optimum load retention and optimized film utilisation.

Delivers unrivalled flexibility

Ring design allows the carriage to be positioned vertically at any height for an unlimited number of wrapping patterns. Octopus Compact 20 is ideal for a range of applications including unstable and lightweight products.

No centrifugal forces - simplifies wrapping difficult loads.

A unique approach to wrapping

Octopus Compact 20 uses an S-type carriage for easy, quick and safe film reel changes. The S-type film carriage design provides less film deflection and better pre-stretch performance compared to a W-type carriage and significantly reduces the overall cost of ownership. Octopus Compact 20 is equipped with a No Touch No Tail system as standard. No Touch No Tail film fixation eliminates film tails and prevents the device from contacting the load itself.

Continuous adjustment of the film tension force relative to the load

Each wrapping pattern has customized loading forces for individual parts of the load for improved load retention.

Additional standard features

- Safety guard with electric interlock

- OctoFACE HMI - for improved visual contact with the user

Options

- Film lashing device: improves load stability with stretch film that wraps around the bottom layer or base of the pallet

- Tail tightening system: tightens the film at the end of the cycle and tucks the tail under the layers to eliminate loose tails

Technical data

- Power supply: 3 x 400VAC/50Hz + N + PE

- Earthing: 16mm² separate cable to the earth rail of the machine

- Power supply: 7.0 kW, 3 x 20A to customer fuses

- Compressed air supply: min. 0.6 MPa, provided by the customer

- Air consumption: 9 Nl/wrapping cycle

- Working temperature: from +5ºC to +35ºC

Capacity calculation

Calculation is based on a wrapping example according to the following data. Changes in any data will affect the calculation:

- Conveyor speed 15m/min, wrapping conveyor length inside Octopus 3000mm, palletized goods infeed and outfeed simultaneously, conveyor transport time 15 sec.

- Wrapping method: double wrap from above

- Product height: 1600 mm, including pallet

- Total number of turns: 30

Wrapping capacity: 31 pallets/hour, including conveyor time

Delivery time from the manufacturer's factory: 20-30 weeks. We will inform you of the exact delivery date after placing your order on the website.