|

Quantity

|

Total

|

||

|

|

|||

In the modern world, automation of production processes is one of the main conditions for increasing efficiency and reducing production costs. One of the key solutions for achieving these goals are orbital packaging machines. These high-tech devices can significantly increase the productivity of enterprises, reduce the time of product packaging and ensure reliable protection of goods during transportation. Due to their flexibility and versatility, orbital packaging machines are suitable for enterprises in various industries - from small production to large industrial companies.

OPERATING PRINCIPLE OF ORBITAL PACKAGING MACHINES

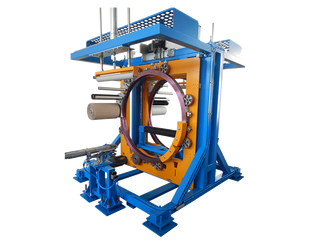

The basic operating principle of orbital packaging machines is that they rotate a roll of stretch film around a product located on a conveyor belt or other moving platform. During the packaging process, the product moves through the machine, and the film is wrapped around it, providing a hermetic and uniform coating.

Since the film is pulled from a roll rotating in an orbit around the product, this allows for high packaging speeds without compromising the quality of the packaging. Thanks to the rotary ring technology, the film is stretched and evenly distributed over the entire surface of the product, which provides reliable protection against external influences such as moisture, dust or mechanical damage.

TYPES OF ORBITAL PACKAGING MACHINES

Orbital packaging machines can be classified according to the size of the products they can process and the level of automation. Depending on the needs of the enterprise, there are different types of machines that can be adapted to the specific requirements of the production process.

Machines for small products

These machines are designed for packaging small sizes, such as metal or plastic parts, wooden blocks, tubes, profiles and other products with a small diameter or short length. Their compact dimensions allow such machines to be integrated even into small production lines.

They are ideal for packaging products that require fast and economical packaging with minimal film consumption. Despite their compact dimensions, the machines provide a high level of productivity, making them suitable for use in enterprises with medium production volumes.

Machines for medium-sized products

Medium-sized packaging machines are used for packaging large products such as metal profiles, furniture parts, household appliances, doors, windows, etc. These machines have a larger ring diameter and the ability to handle products of different lengths.

Due to their high productivity and process automation, these machines can be easily adapted to the needs of large manufacturing plants. They minimize operator intervention and ensure a continuous packaging process, which reduces the risk of downtime.

Machines for large and long products

These machines are used for packaging large and long products such as insulation panels, wooden or metal beams, pipes, building materials, etc. They have a large ring diameter and handle products of great length and weight.

Machines for large products are usually equipped with powerful conveyor systems that ensure smooth movement of goods during packaging. This is especially important for heavy and bulky products, where proper feeding and transport are critical.

ORBITAL WRAPPING MACHINE WORKING RANGE

The working range of orbital wrapping machines is determined by the diameter of the ring used for wrapping the film, as well as the possibilities of film width, rotation speed and film tension adjustment. The main technical parameters that affect the working range of the machines include:

- Ring diameter: Depending on the model, the ring diameter can vary from 400 mm to 2000 mm. This allows for the processing of products of different sizes, from small parts to large-sized goods.

- Film width: Orbital machines usually work with film widths from 125 to 250 mm. This allows for the use of different types of packaging materials, depending on production requirements.

- Rotation speed: The rotation speed of the ring usually ranges from 60 to 200 rpm, which determines the speed of the packaging process. Higher speeds reduce packaging time and increase productivity.

- Film tension adjustment: With the ability to adjust the film tension, orbital machines ensure optimal use of materials, reducing the risk of product damage and saving on film costs.

ADVANTAGES OF ORBITAL PACKAGING MACHINES

Orbital packaging machines offer a number of advantages that make them indispensable for companies looking to optimize their production processes:

- Automation of the packaging process: Thanks to the complete automation of the process, the machines reduce operator intervention and minimize the human factor in the packaging of products.

- Saving materials: The technology of the rotary ring and adjustable film tension significantly reduce the consumption of packaging materials, which leads to savings on film costs.

- Speed and productivity: High ring rotation speed and powerful conveyor systems ensure a continuous packaging process even for large volumes of products.

- Versatility: The machines can be configured to work with various types of products, including large and heavy items, small parts, furniture and building materials.

- Reliability: High quality materials and components ensure durability and reliability of orbital packaging machines, which allows them to be used in harsh production conditions.

- Product protection: Stretch film packaging provides reliable protection of products from external factors such as moisture, dust, mechanical damage and other impacts during transportation or storage.

APPLICATION OF ORBITAL PACKAGING MACHINES

Orbital packaging machines are used in a wide range of industries, such as:

- Metallurgical industry: packaging of pipes, profiles, metal products.

- Construction industry: packaging of insulating materials, wooden beams, panels, bricks.

- Furniture industry: packaging of furniture parts, doors, windows.

- Household appliances production: packaging of large equipment for transportation.

For enterprises seeking to improve the efficiency of packaging processes, orbital packaging machines from SKLADPACK will be a reliable and cost-effective solution. Thanks to their versatility, high productivity and adaptability to different types of products, these machines will help make production more modern and competitive.