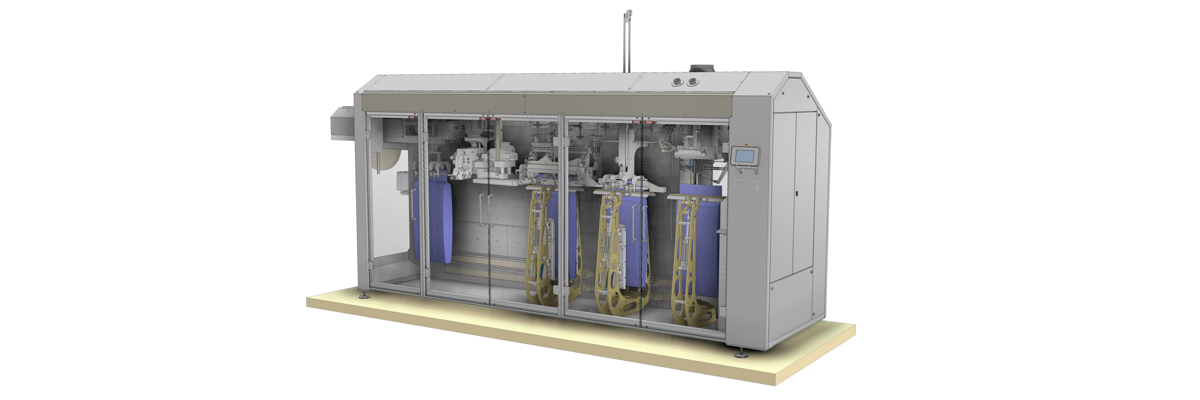

The product is filled into open bags in the automatic Autopac 5.46 (Easy Clean) filling machine, the product weight is controlled by the built-in weighing device. The EC 5.46 is built without the use of square or rectangular profiles, which means that bacteria cannot be trapped when they enter the machine.

The Autopac EC 5.46 is a new fully automatic bag filler with an emphasis on hygiene and operability, consisting of five modules:

1. Filling

2. Vacuum packaging

3. Sealing

4. Stitching | Gluing

5. Closing | Bag outlet

There are doors at the back of the machine that provide access to the drives and electrical components. Since a partition separates the electronics from the bag filling process, the user can monitor and adjust the motors and electronics without stopping production.

The presence of a partition also means that the rear side is protected from dust and small particles, as well as from water, because the front part is cleaned by washing.

The filling machine is equipped with one operator. The operator must clean the filling equipment as needed, the estimated duration of maintenance stops is no more than 2 hours per week.

The empty bag feed magazine has been changed. Now the operator places several packs of bags on a special conveyor, which ensures their constant supply. The new mechanism performs a controlled opening of the top of the bag and its movement on the dispenser clamp. Thus, the probability of bag rejection is significantly reduced.

The possibility of integrating the EC 5.46 with a bag forming unit from a sleeve has been preserved to ensure that the equipment complies with FFS technology.

The conveyor can be made in two versions:

- with metal parts made of aluminum and sprayed steel;

- made of stainless steel.

Each conveyor system is developed based on the Customer's technical specifications.

The new abbreviation in the model name - EC, stands for EasyClean.

The standard version of the machine assumes the use of stainless steel only in the elements that come into contact with the product. However, a machine made entirely of stainless steel can be offered as an option.

However, the choice of settings is not limited to the design options, but includes many useful applications, from the bag shaker during the filling process to the machine's protective guards.

All Autopac series filling machines will now be produced in the new version.

We can offer our customers several feeders according to the physical characteristics of the product, for example:

- sector valve for free-flowing granules;

- screw for products prone to caking and arching;

- belt conveyor for large fractions.

Applications for bulk material packaging:

- food industry: flour, milk powder, food additives and spices, feed;

- chemistry - powders, fertilizers;

- construction industry - dry mixes.