|

Quantity

|

Total

|

||

|

|

|||

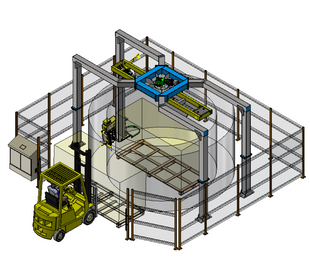

Modern enterprises increasingly prefer automation of production processes in order to reduce costs, increase productivity and ensure the quality of their goods. One of the key links in the logistics chain is the process of packaging finished products. This is where semi-automatic pallet wrappers come to the rescue, allowing you to quickly and reliably pack products on pallets before transporting or storing them. They are ideal for enterprises of any size and industry that are looking for efficient and reliable solutions.

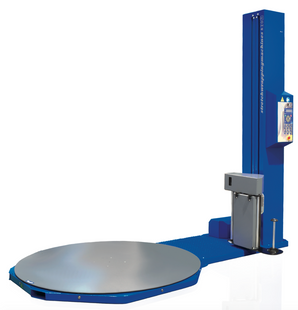

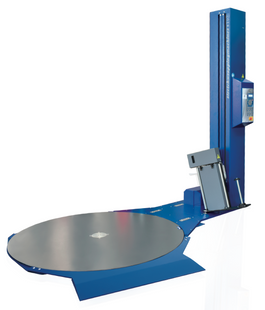

A semi-automatic pallet wrapper (palletizer) is a device designed to automate the process of wrapping goods with stretch film on pallets. The machine ensures uniform and secure fastening of products on a pallet, which prevents them from being damaged during transportation. Such systems are used in various industries, including the food industry, construction, logistics and the production of household appliances.

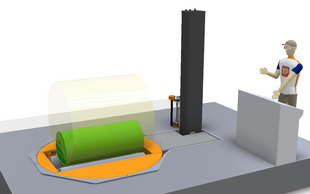

The operating principle of semi-automatic pallet wrappers (palletizers) is quite simple. The operator places the load on the pallet wrapper platform and secures the end of the stretch film on the pallet. After that, the machine automatically starts wrapping. The platform or console rotates, and the carriage holding the film roll moves up and down, evenly distributing the film around the load. The operator can adjust the platform rotation speed, film tension, number of layers and other parameters depending on the needs. The process is complete when the film completely wraps the load. The operator cuts the film manually or, in some models, the machine automatically cuts it at the end of the cycle.

MAIN COMPONENTS OF A PALLET WRAPPING MACHINE

1. Rotary platform or console - this is the main part in which the pallet with the load is placed. The platform rotates, ensuring even wrapping with film.

2. Film carriage - holds a roll of stretch film and can move vertically along the load, ensuring even wrapping from bottom to top and back.

3. Film tension system - allows you to control the degree of film tension, which ensures the density and reliability of the packaging. This allows you to save film and increase the efficiency of packaging.

4. The control panel is an electronic system that allows the operator to set all the necessary parameters: the speed of the platform rotation, the number of film layers, the tension force and other settings that ensure the adaptation of the packaging process to the requirements of the cargo.

ADVANTAGES OF USING SEMI-AUTOMATIC PALLETIZERS (PALLET WRAPPERS)

1. Saving time and resources: Manual pallet wrapping requires a significant investment of time and effort, especially when it comes to large volumes of products. Semi-automatic pallet wrappers significantly speed up this process. The operator spends a minimum of time preparing the pallet, while the machine does the main work - wrapping.

2. Reducing film costs: Thanks to precise control over the wrapping process, the machines allow you to save on stretch film. The film pre-stretching system allows you to use it more economically, without reducing the quality of the packaging. As a result, this reduces material costs and makes the process more profitable.

3. Reliable packaging: Semi-automatic palletizers ensure uniform distribution of the film over the entire surface of the cargo, which makes the packaging more durable and resistant to external influences during transportation. Thanks to this, the products are better preserved and are less exposed to the risk of damage.

4. Reducing the risk of product damage: Thanks to precise adjustment of the film tension, the cargo is not subjected to excessive pressure, which prevents its damage. This is especially important for fragile and pressure-sensitive goods that can be damaged if improperly packaged.

5. Easy integration into existing production processes: Semi-automatic palletizers can be easily integrated into existing logistics processes at the enterprise. Due to their compact size and ease of operation, they can be used in any production environment, regardless of the size of the enterprise.

6. Ergonomics and convenience for the operator: When working with semi-automatic palletizers, the operator does not need to perform heavy physical work, as is the case with manual packaging. All difficult stages, such as tensioning and wrapping the film, are performed automatically by the machine. This reduces the risk of injury and increases overall comfort of work.

Semi-automatic pallet wrappers (palletizers) are widely used in various industries where there is a need for fast and reliable packaging of products.

Main areas of application

- Food industry: for packaging food products protected from moisture and dust.

- Construction industry: for transporting building materials that require reliable fastening on pallets.

- Logistics and warehousing: for fast and safe transportation of various goods, in particular, when delivering over long distances.

- Household appliances and electronics industry: for protecting sensitive products from mechanical damage during transportation.

Semi-automatic pallet wrappers (palletizers) are a reliable and cost-effective solution for any enterprise seeking to automate the packaging process. They not only ensure high-quality packaging, but also reduce material costs, increase productivity and ensure the safety of products during transportation.

SKLADPACK offers a wide range of semi-automatic pallet wrappers that meet the needs of your business. Thanks to our products, you can optimize packaging processes, reduce costs and increase the efficiency of your enterprise. Automate packaging with us - and you will see how this will help your business develop and reach new heights!