|

Quantity

|

Total

|

||

|

|

|||

Country of origin: Sweden

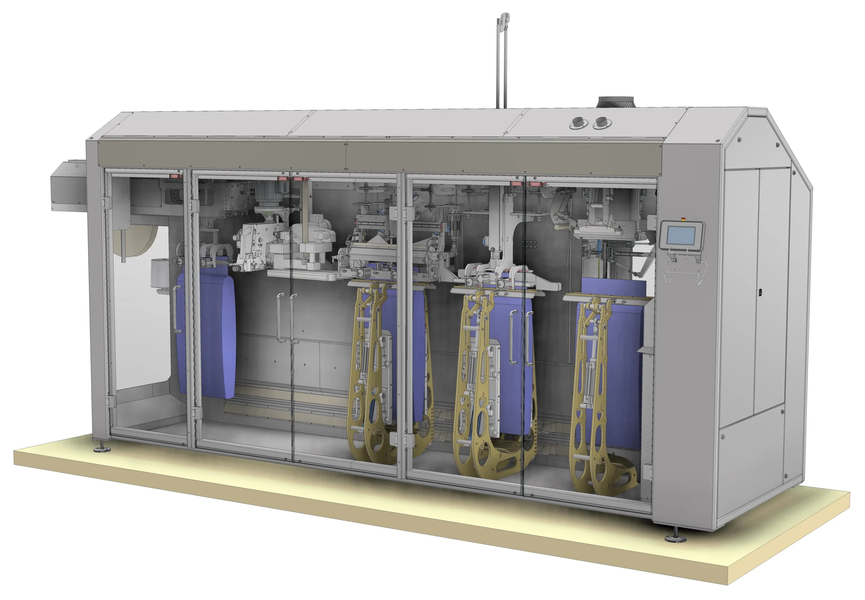

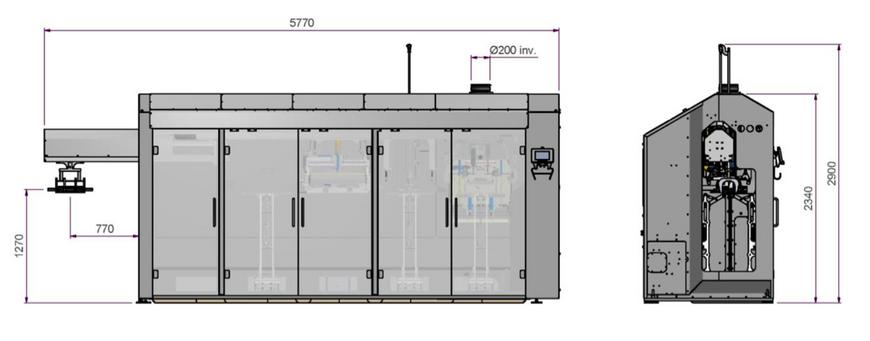

Autopac 5.46 (Easy Clean) automatic filling machine provides precise weight control with a built-in weighing device. Empty bags are fed automatically from a magazine located on a conveyor belt, 3 meters long, which can accommodate about 4 stacks of 80 bags each. After filling, the bags are automatically sealed, sealed by sealing the inner liner and sewing, and then removed by a manipulator outside the machine. The efficiency of the equipment is ensured by one operator responsible for monitoring the process and regular cleaning of the filling equipment, the optimal duration of maintenance stops should not exceed 2 hours per week.

All elements of the filling and packaging line are controlled and monitored by reliable industrial Siemens controllers. Emergency stop buttons are located along the perimeter of the entire line.

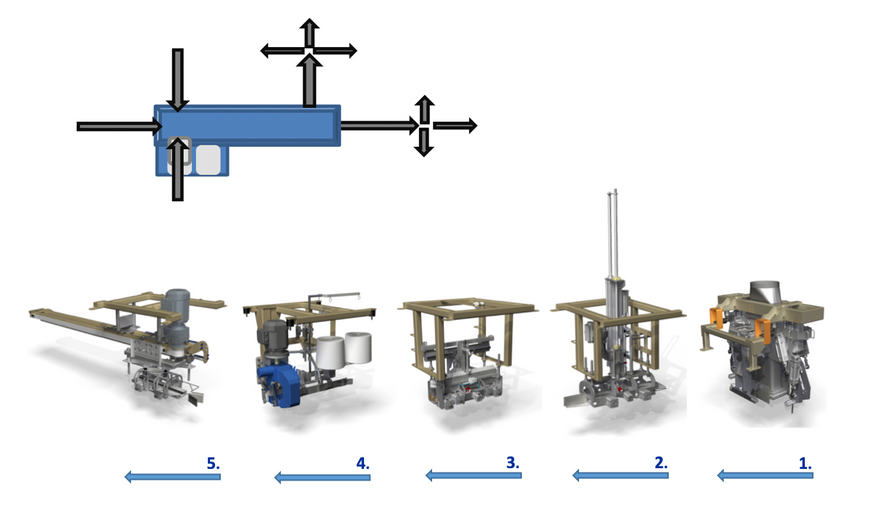

Autopac machine is modular and consists of five modules, each of which performs specific functions related to the packaging process:

1. Filling module: includes a magazine of empty bags, automatic placement, dosing and gross weighing, as well as a clamp (special holder) without dust and a tensioner for the top of the bag.

2. Vacuum packaging: involves opening the top of the bag using suction cups, inserting a filter element, and removing air from the bag to achieve 80% vacuum.

3. Sealing: involves cleaning the sealing area with compressed air, sealing the liner using an impulse sealer with temperature control.

4. Stitching/gluing: implies high-quality stitching using the Fischbein M100 system, with trimming the top of the bag and double stitching.

5. Stacking: finished bags are automatically placed on the output conveyor.

Autopac 5.46 (Easy Clean) is equipped with a 300 litre pre-hopper, an agitator to prevent product compaction and a sector valve for feeding. Ventilation systems and cleaning devices ensure high hygiene.

A high level of safety is achieved due to the reliable bag grip, self-diagnosis with warning functions and the possibility of remote adjustment of the equipment. The accuracy of measurements is confirmed by compliance with European directives. Autopac 5.46 ensures quick installation due to its modular design, which makes it easy to adapt the machine to customer needs and reduces installation costs.

Autopac 5.46 (Easy Clean) is a fully automated system for filling open bags, consisting of a 4600 mm long frame. The unique design includes a bag feeder that gently grips and places the bag on the clamp for subsequent filling. One of the key features is the presence of a clean bottom of the bags, which greatly simplifies the cleaning and modification of the equipment.

System also includes a transport trolley that ensures efficient movement of the suspended bags, while the bag carrier unloads them onto the exit conveyor. The automated design integrates the functional valves and the air preparation station, which are securely protected in a special cabinet. The entire system is supplied with pneumatic components from SMC, electronic modules with Siemens S7 controllers, and has the ability to be remotely accessed via a VPN connection using a 3G router or Cisco client. A color touch screen provides convenient control of the machine operation.

Equipment software includes many useful functions, including recipe processing for quick and safe product changes, production statistics with detailed accounting of the number of bags released, total and average weight, as well as machine productivity. In addition, the system can measure downtime, has alarm functions with a history log and access control options using different passwords.

Net weighing process (measurement without packaging) is started when changing a bag, which helps to increase the overall productivity of the machine. The upper part of the equipment is equipped with an input flange, which is connected to the dosing device, and three weighing cells. To ensure easy access for maintenance, the door, which allows inspection and cleaning, functions on all four sides.

Weighing hopper has a capacity of 70 liters with rounded corners, and its lower part compensates for the pneumatic mechanism, which ensures fast and safe unloading. The hopper door closes tightly with an overlap, which eliminates the need for gaskets. The module is approved by SP (technical studies) in accordance with MID directives, which regulate automatic scales, ensuring high accuracy and reliability.

Safety jaws, which gently squeeze the square section bags, are pneumatically controlled, closing the filling valve when changing bags. It is also envisaged that the jaws are equipped with maintenance-free safety sensors, which control the correct positioning of the bags before starting the filling process. Special sets of clamps are adapted for use with different bag sizes.

Weighing module, integrated directly into the control unit, offers measurement accuracy with a permissible error of ±50 g. The empty bag magazine feeding the machine uses a 3 m long conveyor belt and can accommodate about 4 packs of 60-80 bags each.

Bag shaker is activated according to programmable recipes, shaking the bag vertically using a pneumatic cylinder to achieve uniform filling. The pressure plates, mounted on the trolley, also form the bag and hold it during filling. The sealing module cleans the sealing area with compressed air before impulse sealing of the liner.

Sewing machine is located in a sealed case with pressure lubrication, which ensures effective closure of the upper part of the bag with two threads. Each thread is equipped with a separate wire guard that monitors its operation and detects possible ruptures.

Also included is a device for assembling the bag, folding the upper part before sending it to the sewing machine.

OPTIONS: The dust filter, cleaned with compressed air, assumes long-term operation of the machine. It is made of standard steel with an aluminum air tank. The filter bag is easily replaced through a door on the bottom of the filter. The filter fans are installed on top, and the dust container inside is easily removed for cleaning.

Delivery time from the manufacturer's factory: 5-8 months. We will inform you of the exact delivery date after placing an order on the website.