|

Quantity

|

Total

|

||

|

|

|||

Country of origin: Sweden

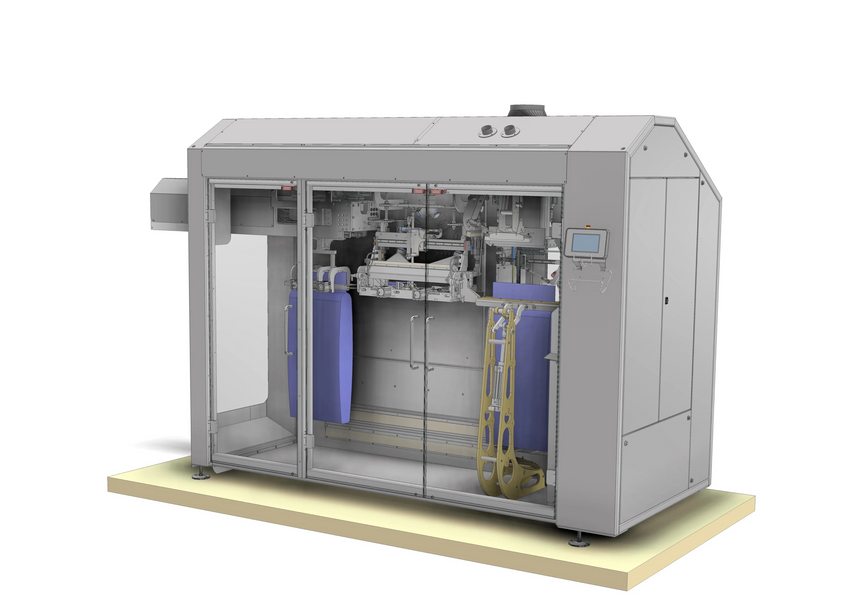

Product is filled into open bags using the automatic Autopac 3.30 filling machine. The product weight is controlled by a built-in weighing device. Empty bags are automatically fed using a feeding unit from a magazine equipped with a 3-meter long belt conveyor. After filling, the bag is automatically sealed by sealing the inner liner and then removed outside the machine by a manipulator. All these operations are controlled by one operator, who is also responsible for cleaning the filling equipment if necessary. The expected hour of downtime for maintenance is no more than 2 hours per week.

Operation of the entire filling and packaging line is controlled by Siemens industrial controllers, ensuring the coordinated operation of units and assemblies, such as a palletizer and a pallet wrapper. The working areas of these units have protective fences and are equipped with automatic locks and light barriers to limit access during operation. In addition, emergency stop buttons are located along the perimeter of the line.

Autopac filling machine has a modular design, the Autopac 3.30 model consists of three modules:

1. Filling module: automatic bag placement, dosing and gross weighing, dust-free bag clamps, bag top tensioner.

2. Sewing module: high-quality Fischbein M100 sewing system is used, bag top trimming and bending, double thread stitching, thread breakage control.

3. Stacking/removal module: transfer of the filled bag to the output conveyor with the possibility of rotation.

Autopac 3.30 (Easy Clean) equipment

- Pre-hopper with a capacity of 300 liters with a flange diameter of 200 mm and minimum and maximum level indicators

- Agitator preventing product compaction in front of the dosing screw, which is equipped with a gear motor.

- Pneumatically controlled sector valve for coarse and fine feed.

- Automatic module control and cleanliness control ensure easy cleaning and a clean bag bottom.

Advantages of the Autopac 3.30

- High hygiene: no bottom bag support, easy cleaning, convenient adjustment.

- Safety: reliable bag grip during the process, self-diagnosis and warning functions, remote adjustment option

- Accuracy: integrated scale and controller ensure precise dosing and compliance with European measuring instrument directives.

- Ease of use: modular design allows quick testing, installation and adjustment.

Additional features

- Modular design without internal conveyor ensures a clean bag bottom and quick change of bag formats.

- Touch display with software for recipe processing, production statistics, downtime measurement and alarm functions.

Machine supports connection to the remote service network and is equipped with an aspiration system for cleaning.

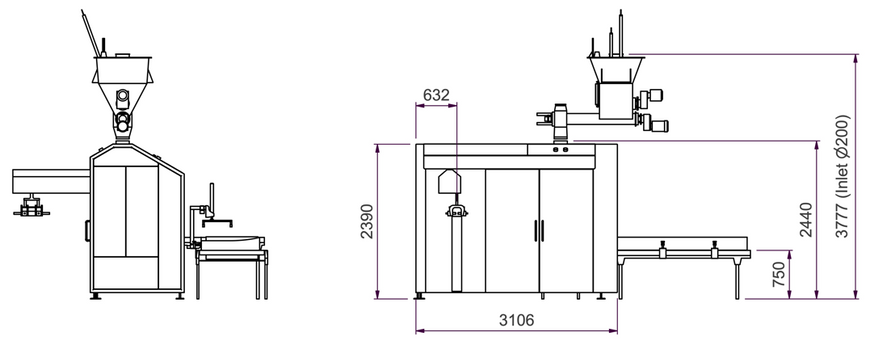

Autopac 3.30 (Easy Clean) is a fully automatic machine for filling products into open-type bags. The design includes a 3000 mm long frame and a bag feeding system that automatically takes the bags and fixes them for subsequent filling. The filled bags are transported using a special trolley, ensuring a clean bag bottom, quick modification of the machine and easy maintenance. The transport system also moves the bags to the original conveyor. Most of the key components, such as valves and the air preparation system, are securely protected in a special cabinet. The pneumatic elements are manufactured by SMC, and the electronic components are equipped with a Siemens S7 controller with the ability to remotely connect via VPN (3G router or Cisco client). Control is via a touch color display.

Machine is equipped with software that supports:

- Recipe processing for quick product changes.

- Production statistics tracking, including number of bags produced, total and average weight, machine performance, and production curves.

- Downtime measurement.

- Alarm event log.

- Access control system with password protection for different user levels.

Net weighing system ensures accurate product weight measurement during bag loading and bag changes, increasing machine efficiency. The top of the machine is equipped with a flange for connection to the dosing device, as well as three weighing cells. Service doors are located on four sides, providing easy access for cleaning and maintenance. A connection for an aspiration system is also provided.

Filling hopper has a capacity of 70 liters and rounded corners, which makes it easy to clean. The pneumatic hatch control system allows the hopper to be fully opened for fast and safe unloading. The doors close tightly with an overlap, eliminating the need for additional seals. The weighing module is certified according to the requirements of the European MID Directive for automatic scales, and the measurement accuracy is ±50 g.

Square-neck bags are fixed with pneumatic clamps. They are equipped with sensors to check the correct installation of the bag before filling it. The machine supports the ability to work with bags of different sizes. The bag top expander forms its flat top for subsequent sealing. The components are made of stainless steel grade EN 1.4301, which ensures durability and reliability.

Siemens SIWAREX FTA weighing module is integrated directly into the control controller, which allows for highly accurate weighing of the product.

Empty bag feeding system is implemented using a 3-meter belt conveyor, which can hold up to 5 packs of 80 bags each. The main structural elements are made of aluminum and carbon steel.

Bag shaker is activated according to the recipe and ensures uniform filling of the bag using a pneumatic cylinder. The pressure plates on the trolley help to form the bag and fix it during transport.

Sewing machine used to hermetically seal the bag is equipped with a pressure lubrication system and a filter, which ensures reliable operation. It closes the bag with two threads, and a separate protection system for each thread is used to monitor the operation. If a thread breaks, the system issues a malfunction signal.

Bag assembly module bends its upper part before entering the sewing machine. The main components are made of stainless steel grade EN 1.4301, which ensures high wear resistance.

OPTIONS: The machine can be additionally equipped with a dust filter, cleaned with compressed air for long-term trouble-free operation. The filter is made of ordinary steel, has an aluminum air tank and replaceable filter elements.

Delivery time from the manufacturer's factory: 5-8 months. We will inform you of the exact delivery date after placing an order on the website.