|

Quantity

|

Total

|

||

|

|

|||

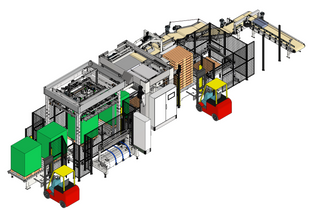

Automation of palletization is an important aspect of modern production and logistics processes, which allows to significantly increase efficiency, reduce costs and ensure smooth operations. This process not only minimizes the risks of human intervention, but also guarantees high productivity, which is a key factor in the successful operation of enterprises. Automated palletizing systems, such as those offered by Skladpack, optimize the stacking of products on pallets and facilitate their further transportation. This solution opens up new opportunities for businesses seeking to achieve maximum efficiency.

The main advantages of automated palletization include

1. Increased productivity. Automated systems work significantly faster than manual processes, which allows you to process more products in less time. This is important for enterprises where every minute of downtime can lead to significant losses. For example, the automatic bag palletizing line PAL 1100 processes up to 800 bags per hour, which significantly increases the efficiency of the production process.

2. Reduced costs. Automation of processes allows enterprises to reduce costs for labor, materials and energy resources. For example, automated systems can significantly reduce the use of packaging materials such as stretch film by optimizing the packaging process. In addition, reducing the need for manual labor reduces labor costs and social benefits for workers.

3. Increased safety. The implementation of automated solutions minimizes human involvement in dangerous operations, such as heavy lifting equipment or handling large loads. This significantly reduces the risk of injury, which in turn reduces insurance costs and payments in the event of accidents. For example, the PM800-9 palletizer ensures a continuous process of palletizing goods, reducing the need for human intervention and increasing overall safety.

4. Accuracy and quality of palletizing. Automatic palletizers ensure high accuracy in palletizing products, which reduces the risk of damage during transportation. The use of technologies such as a sliding plate or pusher system allows for precise layering of products and ensures their stability on pallets. This is especially important for products such as building materials or beverages, where errors in palletizing can lead to significant losses.

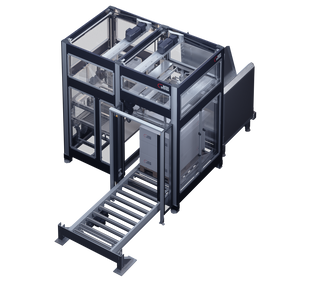

5. Flexibility and adaptability. Modern automated systems, such as the Single Compact 128LV, can be easily adapted to different product types and production conditions. Thanks to their modular design and customization options, such systems can be quickly re-equipped to handle new types of packaging or products. This allows companies to quickly respond to market changes and customer requirements without losing efficiency.

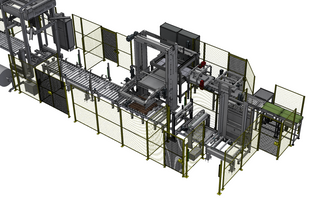

6. Integration into existing production lines. Automated systems can be easily integrated into existing production lines, avoiding complex and expensive modifications to equipment. This reduces the costs of implementing new technologies and ensures uninterrupted production. For example, Skladpack offers solutions that can be integrated into various types of production lines, ensuring high productivity and reliability.

7. Upgradeability. Automated palletizing systems can be easily upgraded, allowing companies to stay current with technology without completely replacing equipment. This also allows for the rapid implementation of new solutions to improve efficiency and reduce costs.

Thanks to these advantages, automated palletizing is becoming an integral part of modern production. Companies implementing such systems can increase their competitiveness, reduce operating costs and improve the quality of their products. In the context of modern business, where speed and accuracy are decisive factors, automated systems ensure a continuous production process and contribute to achieving high results.

Thus, choosing automated palletizing systems from SKLADPACK is a strategically important decision for any company striving to achieve high productivity and efficiency. Our solutions will help you optimize production processes, reduce costs and improve overall safety in production, ensuring the sustainability and resilience of your business.