|

Quantity

|

Total

|

||

|

|

|||

Country of origin: Denmark

Once the case has been assembled and sealed at the bottom with adhesive tape, the crate is ready for further filling.

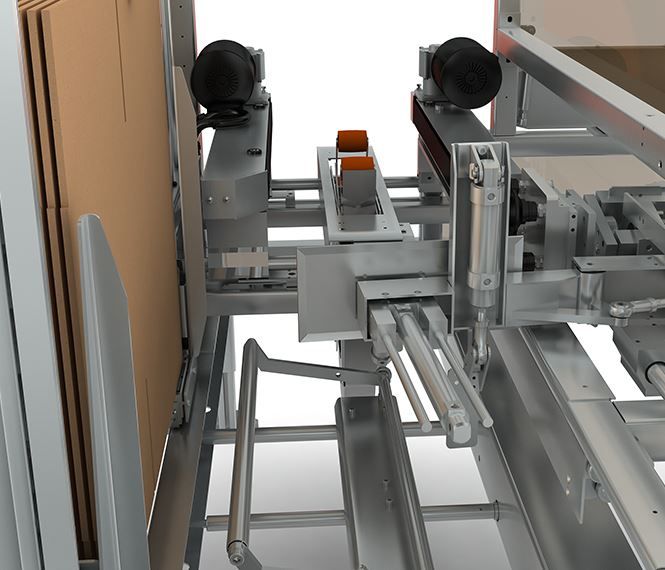

SOCO Pack ATS is an impressive automated case erector machine that operates at high speeds and includes an integrated mechanism for sealing the bottom of the crate with adhesive tape.

As standard, this machine is capable of handling crates that comply with the FEFCO 0201 standard.

Among the additional functions that can be integrated into the case erector is a side flap slider, which can be useful in cases where the material quality or the design of the crates does not meet the requirements. It is also possible to configure the machine to handle crates with closing side flaps.

SOCO SYSTEM case erector is the ideal solution for starting a packaging line, as it significantly improves ergonomics, as well as increases productivity and automation of the entire process.

The pneumatic components of this picker come from Festo, while the programmable logic controller (PLC) system is based on Siemens components.

This compact machine is easy to install in any environment, has a user-friendly software with extensive capabilities, and is characterized by low noise levels and efficient air consumption, making it an excellent choice for modern production.

TECHNICAL SPECIFICATIONS

Box dimensions (max.): 830 x 440 x 550 mm

Box dimensions (min.): 265 x 190 x 150 mm

Productivity: up to 12 boxes/min

Cardboard store volume: approx. 190 pcs

Electrical characteristics: 0.5 kW, 400 V, 50 Hz

Air consumption: 38 l/cycle, min. 600 kPa

Noise level (max.): 74 dBA

Suction plate: variable type

Controller: Siemens PLC

Pneumatic parts: Festo

Color: RAL-9006 (light gray)

Special options: on request

Delivery time from manufacturer's factory: 12-24 weeks. We will inform you about the exact delivery date after placing the order on the website.