|

Quantity

|

Total

|

||

|

|

|||

Country of origin: Sweden

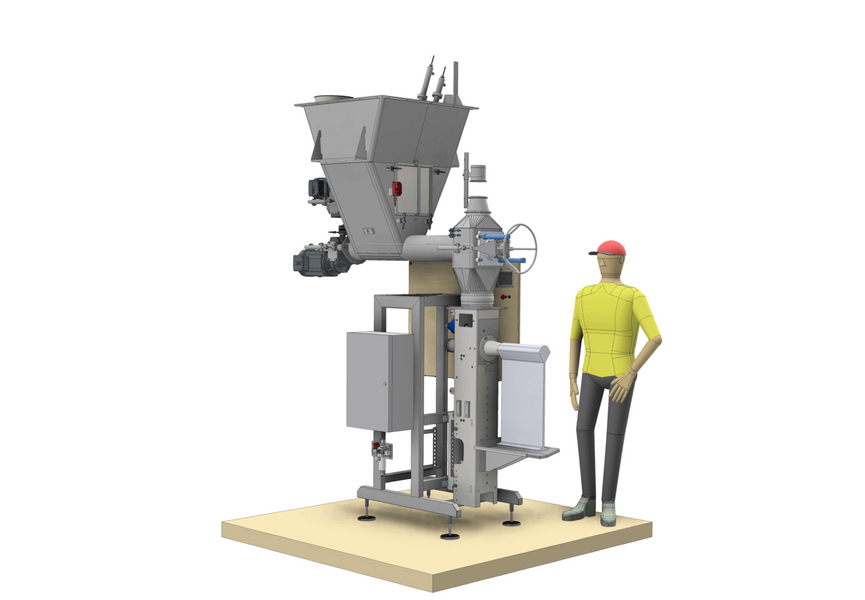

Skruvpac filling machine is a modern valve bag filling machine with high productivity and precision. Empty bags can be fed into the filling machine both manually and automatically. The machine is designed to handle various materials and bag types according to specific technical requirements. Thanks to its clean and compact design, the machine is suitable for various types of products, and its Swedish design ensures reliability and ease of use. The high level of automation and robust design make it an ideal option for use in enterprises of various industries where speed, precision and hygiene of production processes are important.

Main features:

- Automatic valve bag filling: High productivity and precision are ensured by the electronic weighing system.

- Hygienic design: The dosing screw and agitator are adapted for easy cleaning and meet sanitary requirements.

- Materials: Possibility to choose between standard mild steel or stainless steel.

- Mobility: Wheeled installation options make it easy to transport.

- Process automation: Includes automatic bag removal and palletizer for convenience and optimization of production processes.

Technical specifications:

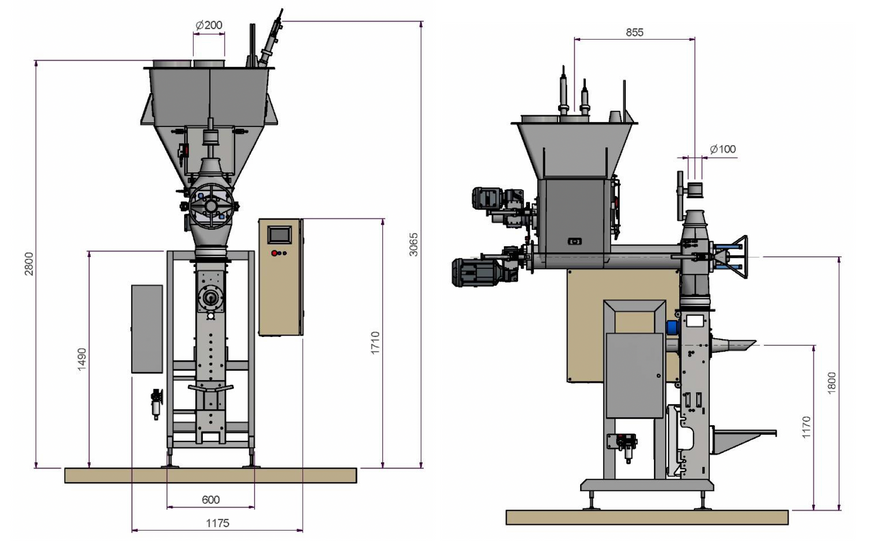

- Dimensions: 900 mm (width) x 2100 mm (length) x 1800 mm (height)

- Weight: 250 kg

- Productivity: Up to 250 bags per hour

- Dosing portion: 10-30 kg

- Power consumption: 3 x 400 V, 2.6 kW

- Air pressure: 6 bar

- Accuracy: +/- 50 g

Compatibility with different types of bags:

- Paper bags

- Paper bags with plastic inner layer

- Plastic bags

- Woven polypropylene bags

Main components of the machine:

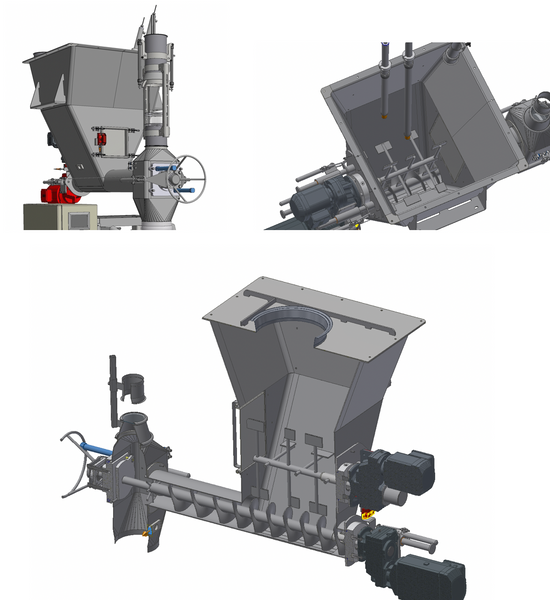

- Aspiration valve: Situated between the outlet of the dosing screw and the dust filter fan. PLC controlled and opens during dosing to prevent dust accumulation. After bag change, the valve closes and dust generated during operation is sucked out to keep the work area clean.

- Raw material hopper: The hopper has a capacity of 300 liters and is equipped with a 200 mm diameter flanged inlet and maximum and minimum fill level indicators. The top of the hopper has an inspection hatch with a 200 mm diameter cover for easy access.

- Hopper agitator: Complies with hygienic standards and prevents the material from clumping before feeding it to the dosing screw. The agitator is driven by a gear motor located on guides for easy maintenance and cleaning.

- Dosing screw: Also adapted to hygienic requirements. The auger helical screw can be easily pulled out for cleaning. The pneumatically controlled valve ensures high dosing accuracy and the auger drive is mounted on guides for easy maintenance. - Siemens SIWAREX FTA weighing module: Connected to the S7 control system and ensures accurate weight measurement. The automatic scale is integrated into the machine frame, ensuring reliable operation and compliance with international standards.

- Adjustable bag support unit: Can be easily adjusted in height for convenient handling of different types of bags.

- Pneumatic bag tipper: Automatically transports filled bags to the conveyor for further processing.

- Electrical cabinet: Equipped with a Siemens S7-1500 controller, which controls all machine functions. The operator panel with a color touch screen allows convenient adjustment of operating parameters.

Electrical system:

Machine is equipped with a cabinet with a Siemens S7-1500 controller, which controls all filler functions, including an operating panel with a touch screen for convenient operation.

All electrical equipment meets the Swedish standard SS-EN 60204 with protection class IP 55.

Delivery time from the manufacturer's factory: 5-8 months. We will inform you of the exact delivery date after you place your order on the website.