|

Quantity

|

Total

|

||

|

|

|||

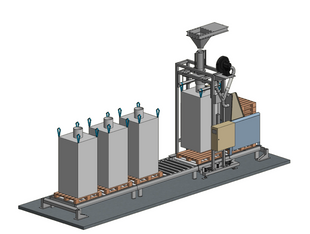

Automation of the processes of filling and processing products in big bags is a key factor in the successful operation of many enterprises in various industries. Big bag processing lines allow you to efficiently process large volumes of goods, ensuring accuracy, speed and safety at every stage of the production process. The use of big bags (large bags for bulk materials) significantly simplifies the transportation and storage of products, which makes these systems an integral part of the work of enterprises in such areas as agriculture, chemical industry, building materials, etc.

Big bag processing lines are complex automated solutions that allow you to fill, transport, weigh and pack products in big bags as efficiently as possible. Bags are used to transport and store bulk materials such as grain, sand, cement, chemicals. Big bag processing equipment ensures accurate dosing, automatic loading and hermetic sealing of bags, which guarantees the safety of products and minimizes losses.

Modern automated lines allow enterprises to reduce their dependence on manual labor, minimize labor costs, and reduce errors in product packaging. Thanks to the use of high-quality components and advanced technologies, these systems ensure stability and reliability in the processes of packaging and transporting products.

The main advantages of automated lines for processing products in big bags

1. Efficiency and high productivity. Automated big bag filling lines allow you to process a large number of bags in a short period of time. This ensures stable operation of the enterprise and avoids delays in production processes. Thanks to fast automatic loading and weighing of products, the lines can process hundreds of bags per hour, which is an important factor for enterprises with high production capacities.

2. Accuracy of dosing and weighing. One of the main advantages of automated lines is the accuracy of filling big bags. Integrated weighing systems ensure accurate dosing of the product in accordance with the set parameters, which minimizes deviations and saves valuable material. This is especially important for companies working with precious or hazardous materials, where even small losses can lead to significant losses.

3. Reduced labor costs. By automating the process of filling and processing products in big bags, the need for manual labor is significantly reduced. This allows companies to optimize operations and reduce labor costs, as well as reduce the number of errors in the bag filling process.

4. Safety and environmental protection. Automated big bag handling systems are equipped with modern mechanisms for hermetically sealing bags, which ensures complete control over dust or hazardous emissions. This is important for companies working with toxic or harmful materials, ensuring the protection of workers and the environment.

5. Flexibility and adaptability. Big bag handling lines can be configured to handle various types of products and bags. The system easily adapts to changes in production processes, making it a universal solution for companies working with different types of materials. This allows you to quickly reconfigure the equipment to meet the requirements of a specific product or order.

6. Reduced packaging losses and costs. Thanks to precise dosing and hermetically sealed bags, product losses during packaging and transportation are minimized.

7. Integration into existing production lines. Modern big bag processing lines can be easily integrated into the existing infrastructure of the enterprise, which ensures uninterrupted operation and minimizes the costs of upgrading production processes. The system can be fully synchronized with other automated production processes, ensuring a high level of efficiency.

Lines for processing products in big bags perform several key operations

- Filling big bags - automatic dosing and filling bags with products.

- Weighing products - integrated weighing systems ensure dosing accuracy.

- Hermetic sealing - systems automatically close bags after filling, ensuring hermeticity.

- Transportation - automated conveyors move bags to the storage or shipment stages.

- Preparation for shipment - automatic stacking of bags on pallets for further transportation.

SKLADPACK offers comprehensive solutions, including modern lines for processing big bags, automated systems for filling, weighing and transporting products. We offer equipment from leading global manufacturers, guaranteeing reliability, durability and high productivity.