|

Quantity

|

Total

|

||

|

|

|||

Processing and packaging of building materials on pallets requires special precision and reliability, since materials such as bricks, concrete blocks, cement and other large-sized goods require strong fixation for safe transportation and storage. In such conditions, automated pallet processing lines are an important element for increasing enterprise productivity and reducing manual labor costs.

SKLADPAСK offers a wide range of solutions for automating the processes of processing and packaging pallets with building materials. The equipment that you can purchase from the company includes conveyors, pellet wrappers and strapping machines that allow you to automate the stacking, fixing and wrapping of products. Each type of equipment has its own advantages and can be selected in accordance with the tasks of your business.

Strapping: reliable fixation for stable transportation

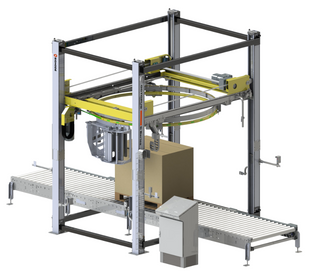

Strapping equipment is an indispensable part of the lines for processing building materials, used for strapping cargo with special polyester or polypropylene straps. This equipment allows not only to pack boxes and crates, but also to group and fix building materials on pallets. Strapping ensures reliable fixation of the load, which is especially important when transporting heavy or fragile building materials.

Strapping machines work with different types of straps, allowing you to adjust the tension level depending on the needs of your production. Vertical and horizontal strapping ensures stability and safety of the load even during long-distance transportation. Additional settings, such as sword collision control and end of tape indication, make the strapping process even more efficient and convenient for operators.

Pellet wrappers: ensuring cargo safety with stretch film

Pellet wrappers are key equipment for ensuring stable packaging of pallets with building materials. They allow you to securely fasten the load on pallets with stretch film, which protects the products from external influences, such as dust, moisture or mechanical damage.

SKLADPACK company offers several types of pellet wrappers

- Classic pellet wrappers provide a simple and reliable wrapping process when the pellet is mobile.

- Ring pellet wrappers work on the principle of rotating the ring around the load, which minimizes the displacement of products during the packaging process.

These systems allow you to save packaging materials thanks to film pre-stretching technologies, which makes the packaging process more economical and environmentally friendly.

Stretch hood machines: maximum protection and sealing

To ensure complete protection of pallets with building materials, SKLADPACK offers stretch hood machines. This solution provides hermetic packaging of products on all five sides, which guarantees protection of the cargo from external factors and damage during transportation.

For example, the Power Flex T1 machine provides effective wrapping of pallets of different heights using cost-effective stretch hood film. This solution is ideal for companies working with goods of the same size and allows achieving productivity of up to 100 pallets per hour.

For more complex tasks, such as handling goods of different heights and pallet sizes, you can use the Multi Flex machine, which is highly flexible and can be adapted to different types of products.

Advantages of automated pallet handling and packaging lines

1. Increased productivity: Automated lines significantly speed up the pallet handling and packaging processes, which allows companies to achieve higher productivity at lower costs.

2. Reduced packaging material costs: Pre-stretch film and strapping technologies help reduce the amount of materials needed to secure the load, making the process more cost-effective.

3. Ensuring cargo safety: Reliable strapping and stretch film wrapping ensure that the load is reliably protected from external factors and remains in perfect condition during transportation and storage.

4. Flexibility and adaptability: The equipment can be configured to work with various types of building materials, regardless of their weight or dimensions.

5. Minimization of human intervention: Thanks to the automation of pallet handling and packaging, the need for manual labor is significantly reduced, which helps reduce human errors and reduce personnel costs.

Automation of pallet handling and packaging with building materials is an important step in increasing efficiency and safety in production. With equipment from SKLADPACK, your pallets with building materials will be reliably processed, secured and ready for safe transportation and storage, ensuring maximum productivity and reliability of your enterprise.