|

Quantity

|

Total

|

||

|

|

|||

Automatic pallet wrappers (palletizers) are an important element of modern logistics and production processes, providing reliable packaging of products for safe transportation. Their use can significantly increase production efficiency and minimize human intervention in the packaging process. These devices automatically wrap pallets with stretch film, ensuring reliable fixation of the goods on the pallet and protection from external influences.

Pallet wrappers work on the principle of wrapping a pallet with a stretched and secured film around the load. In the case of automatic machines, this process is completely controlled by a computer, which ensures uniform tension of the film and correct wrapping. This allows for reliable fixation of the load without the risk of damage or displacement during transportation. Automatic pallet wrappers can work with different types of film depending on production needs and the type of cargo. Most modern models have a pre-stretching film function, which allows you to save materials without losing the quality of the packaging.

KEY BENEFITS OF AUTOMATIC PALLET WRAPPERS

1. Increased productivity. Thanks to the automation of the process, pallet wrappers are able to process large volumes of goods in a short time, which significantly increases the productivity of enterprises.

2. Saving materials. Pre-stretching of the film allows you to use less materials, reducing packaging costs. This is achieved thanks to the technology of stretching the film before applying it to the cargo, which reduces its consumption.

3. Reliability and uniformity of packaging. Automatic palletizers ensure uniform wrapping of the cargo with film, which prevents it from shifting during transportation. This is important to ensure the integrity of the goods and minimize the risk of damage during transportation.

4. Reducing the labor intensity of the process. Automation of the packaging process allows you to minimize manual work, reducing operator intervention in the process. This also contributes to increased safety in production, since operators do not need to be directly involved in wrapping pallets.

5. Flexibility of settings. Many models of pallet wrappers have the ability to adjust the number of film layers, tension and other parameters, which allows you to adjust the packaging process to the specific needs of production.

TYPES OF AUTOMATIC PALLET WRAPPERS

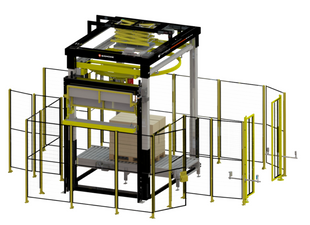

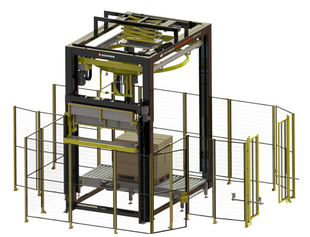

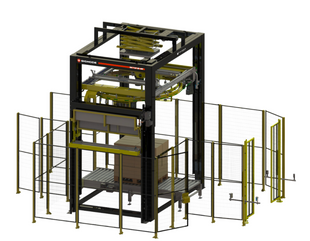

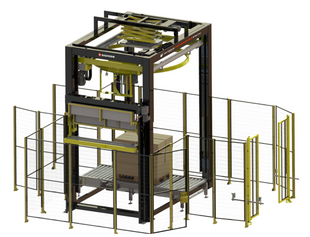

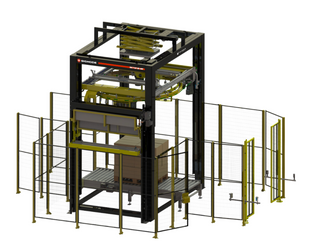

- Ring pallet wrappers. These machines rotate the film around a stationary pallet using a rotating ring. This design ensures high packaging speed and uniform wrapping. Ring palletizers are ideal for large-scale production, where high productivity and packaging quality are important.

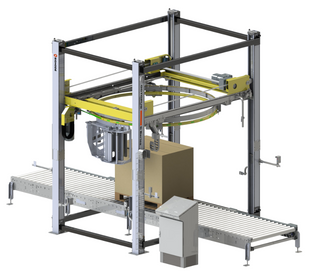

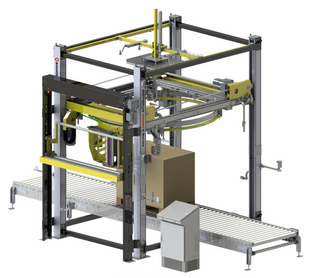

- Pallet wrappers with a rotating arm. In such machines, it is not the pallet that moves, but the arm with the rotating film around the load. This allows them to be used for packing unstable or light loads that can be damaged when rotating on a turntable.

- Pallet wrappers with a rotary table. These are simpler models that rotate the pallet itself around its axis, wrapping it with film. They are suitable for small enterprises with smaller packaging volumes, where high speed is not required.

TECHNOLOGIES USED IN PALLET WRAPPERS

- Film pre-stretching. This is one of the main tools for saving materials, allowing you to use less film during packaging without losing its strength. The film is stretched to the required level before applying it to the load, which ensures maximum use of its strength.

- Film tension control. Automatic machines are equipped with film tension control systems, which allow you to accurately adjust the tension force depending on the type of cargo. This is important to ensure proper protection of goods during transportation.

- Automatic film roll replacement. Some models of pallet wrappers are equipped with automatic film roll replacement systems, which reduces equipment downtime and increases overall productivity.

ADDITIONAL FEATURES AND OPTIONS

In addition to the basic functions, automatic pallet wrappers can be equipped with additional options that increase their efficiency. For example, they can have clamping mechanisms to stabilize the load during packaging or film end welding systems, which ensures more accurate packaging and protection against unwinding. Modern palletizers can also be integrated into general automated production lines, working in tandem with other robotic devices to maximize the efficiency of the production process.

ADVANTAGES OF AUTOMATION OF THE PACKAGING PROCESS

- Reduction of manual labor costs. Automatic machines allow to significantly reduce the number of workers required for packaging, which leads to lower labor costs and increased production efficiency.

- Increased speed of production processes. Automatic pallet wrappers work much faster than manual packaging, which allows to increase the throughput of production lines and process orders faster.

- Improved packaging quality. Due to the automation of the process, the film evenly covers the load, providing better protection of goods during transportation.

SKLADPACK is a leader in the market of packaging equipment supplies and offers a wide range of automatic pallet wrappers for various needs. Here you will find equipment from leading global manufacturers that meets the highest quality standards. Our specialists will help you choose the optimal model of a pallet wrapper that will best meet your requirements and will provide technical support at all stages of operation.