|

Quantity

|

Total

|

||

|

|

|||

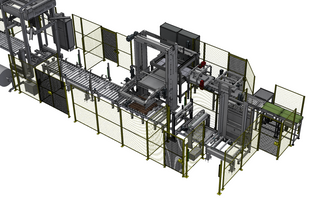

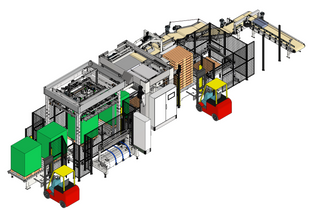

Palletization is an important stage in the logistics process, which has a significant impact on the efficiency of production and storage. Choosing the right palletizing equipment not only simplifies the process of transportation and storage, but also protects products from damage. Skladpack palletizing solutions are powerful, high-performance systems that combine versatility, multifunctionality and ease of operation. Our range includes two main technologies: classic palletizers and robotic palletizers.

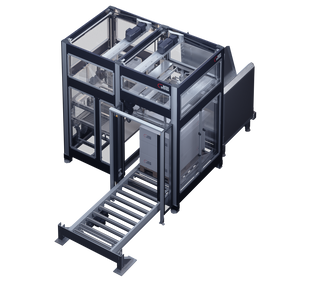

CLASSIC PALLETIZERS

Classic palletizers are reliable machines for palletizing various types of products: packages, trays, sacks, etc. The basic principle of their operation is the formation of rows using a sliding plate system. These machines are ideal for automating production processes, ensuring high speed of palletizing goods.

Advantages of classic palletizers

- Process automation: The machines are controlled by a PLC (programmable logic controller), which allows for flexible settings and the ability to save configurations for different types of products.

- Ease of operation: The high level of automation makes the operation of the equipment simple and efficient, with minimal need for operator intervention.

- Precision and reliability: The pusher and sliding plate system ensures precise formation of layers, which avoids damage to the product during stacking.

- Flexibility of settings: The PLC allows programming of different stacking options, adapting the machine to different types of products.

How does a classic palletizer work?

The products arrive at the layer formation table, where they are lined up in rows according to the specified configuration. The pusher moves the formed layer to the intermediate plate, after which it is placed on the pallet. The process is repeated until a full pallet is formed. Thanks to the automated system for feeding empty pallets and removing full pallets, this process can take place continuously, which significantly increases productivity.

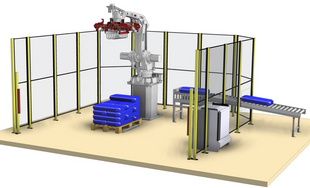

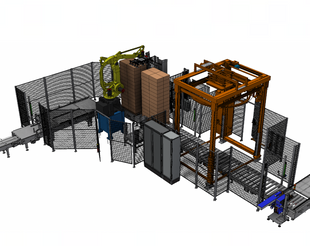

PALLETIZING ROBOTS

Palletizing robots are an innovative solution for fast and efficient product processing. These systems are characterized by high speed and versatility, which allows them to be used for palletizing products of different weights and sizes. They are especially useful for large-scale production, where products come from several lines simultaneously.

Advantages of palletizing robots

- High stacking speed: Robots can work at high axial speed, which reduces the time of one cycle and increases overall productivity.

- Possibility of simultaneous work with several channels: Palletizing robots can serve several product streams, stacking them on different pallets.

- Efficiency in small spaces: Thanks to the 360° coverage area, robots can work even in limited spaces, which makes them an ideal solution for compact production.

- Flexibility in working with different types of products: Robots are equipped with grippers developed according to specific customer requirements. This allows you to stack cardboard boxes, trays, kegs, pallets and other types of products.

How does a robot palletizer work?

The robot picks up products using a special manipulator and carefully places them on a pallet. Due to the high axial speed and programming capabilities, the robot can quickly move goods without damaging them. An important feature is the support of various network protocols, such as DeviceNet, ControlNet, Profibus-DP and Interbus-S, which allows you to integrate the system into the existing production infrastructure.

Why choose a palletizer from Skladpack?

Skladpack palletizing equipment is reliability, high performance and modern technologies that allow you to optimize production processes. Our palletizers can be adapted to different types of products and production lines, which makes them a universal solution for any enterprise. Thanks to high automation and intelligent control systems, our machines ensure the accuracy and continuity of the palletizing process.

Main advantages of the equipment

- Versatility: Our palletizers are suitable for working with different types of products - from bags to kegs and boxes.

- High speed and productivity: Palletizing robots ensure fast product stacking, which increases overall production efficiency.

- Possibility of individual adjustment: We offer the development of special grippers for customer products, which ensures the reliability and accuracy of palletizing.

- Integration into existing systems: Our equipment supports modern industrial standards and can be easily integrated into any production line.

If you are looking for a reliable solution for automating the palletizing process, contact SKLADPAСK. Our specialists will help you choose the best equipment to meet your production needs. We guarantee high quality products, an individual approach to each client and competitive prices. When ordering palletizing equipment from us, you get a powerful tool to improve the efficiency of your business!